Expansion Joint Articles

Expansion joint articles, comparisons, background and history, the EMSEAL knowledge base is a useful tool in selecting, justifying, and understanding expansion joint and sealant selection.

“The common law of business balance prohibits paying a little and getting a lot. It can’t be done. If you deal with the lowest bidder, it is well to add something for the risk you run, and if you do that you…More

An engineer at a firm with which we have shared over 26 years of watertight expansion joint success, was tempted by a “new” technology as an alternate to EMSEAL Thermaflex for parking deck joints. He sent an email asking if we would be…More

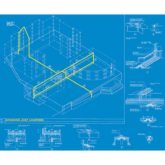

Successful Expansion Joint Treatment—Collaborative, 3-D Design, Detailing, Construction, Fabrication, Installation It’s not just about products. How can we work together to ensure trouble-free building expansion joints? While Sika Emseal prides itself on having high-quality, innovative and durable materials for use in sealing,…More

Is There a Gap in Your Air Barrier Wall Design? Overlooking joint sealing where it really matters–in the structural backup wall. All day long, our specification development team opens and reviews architectural details. We look at cross sections every week. One of…More

Expansion Joint Snow Removal and Maintenance of Parking, Plaza and Stadium Expansion Joints I. GENERAL MAINTENANCE of EXPANSION JOINTS Regular inspection and maintenance of expansion joints will extend their service-life. Once a year, expansion joints should be swept out, vacuumed and inspected…More

“Expansion joints are ugly.” We occasionally hear this objection from architects. Notwithstanding that eye-of-the-beholder thing, it may be true–if you actually see the joints. Most people don’t ever notice expansion joints. They’re certainly not the visual focal point of architecture. As expansion joint material…More

Fire rated expansion joints are evolving to meet advancing building science. Today’s wall systems are being designed and constructed to perform a growing number of functions. Beyond simply separating rooms or enclosing a structure, they are expected to maintain thermal conditions, contain…More

Waterproofing expansion joints must occur at the deck surface. If water leaks through, or is allowed to pass through the primary expansion joint with the intention of using gutters to catch the water, then you are engaged in water management, not waterproofing.…More

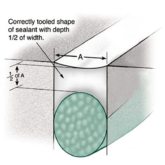

Overcoming Product Limitations: Waterproofing Movement Joints with Hybrid Sealants Abstract Liquid sealants are the most commonly used sealant product for filling joints in building components and structural joints. Yet their performance, particularly in dynamic joints, can suffer from a variety of shortcomings…More

SUMMARY: Waterproofing building expansion joints is in many ways dependent on the selection of the right system for the application at hand. Where properly selected, sized, and installed, Sika Emseal has products that perform well beyond their warranty. Ultimate longevity will be…More

“Hour-Glass” and Tension: Caulk and Backer Rod’s Achilles Heels Liquid sealants are the most commonly used sealant product for filling smaller joints in building components and control joints. Yet their performance, particularly in moving joints, can suffer from a variety of shortcomings.…More

Rethinking Expansion Joints in the Face of Quakes and Hurricanes Expansion joints can be said to be among the most critical aspects of design in relation to building performance under geological and weather extremes. In the wake of the recent earthquakes in Turkey and…More

UL 2079 Certification for Deck and Floor Expansion Joints–What’s involved? UL and ULC Certification of products for deck and floor expansion joints is a rigorous course of upfront product testing and ongoing manufacturing inspection and certification. UL 2079 testing encompasses the burn…More

Shear Pocket Technology Enhances Movement of Deck and Roof Expansion Joints Developed by Sika Emseal over 20 years ago, shear pockets are a loop of Santoprene thermoplastic rubber welded to replace the center member or cells of an expansion joint extrusion. Shear…More

Expansion joints are literally a gap through the insulation of a building envelope. Your choice of technology to fill and seal the gap can set the R-Value of the building assembly. Is Expansion Joint and Sealant Selection Costing Your Client a Fortune?…More

Ice floor expansion joint sealing at ice-floor perimeter joints poses a unique challenge. Sika Emseal has for going on 40-years consistently met this challenge through the use of its precompressed, impregnated foam and foam-silicone hybrid sealants. The latest evolution of this expansion…More

In consideration of the specification of SJS-Seismic Joint System from Sika Emseal Thanks for consideration of the adoption of our SJS System for use on your project. You will find that the SJS System is an evolution of proven existing technologies applied innovatively…More

Sika Emseal’s Backerseal and Seismic Colorseal joint sealants are uniquely suited for use as a component in an air barrier assembly. Seismic Colorseal and Backerseal installed as offered and intended in conjunction with a field-applied, low-modulus, liquid sealant is compliant with the ABAA air barrier performance requirements. …More

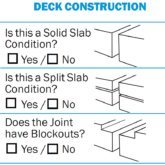

Floor Expansion Cover Joint Selection: Selecting floor expansion joints for lasting function begins with first calculating anticipated LOAD, MOVEMENT, and JOINT-GAP SIZE, then asking and answering the following questions: Can this model handle the loads from my expected traffic? Can this model…More

The General Contractor’s Role in Ensuring Watertight Expansion Joints and Joint Sealants Successful projects with expansion joints and joint sealants that don’t leak are characterized by a collaborative commitment by the A/E team, the general contractor, the joint manufacturer, and the waterproofing…More

What’s the best roof expansion joint design? Our Chicagoland rep, recently asked some good questions: “What is preferred: all pre-compressed foam joints for roof and walls or RoofJoint with foam for verticals? What are the criteria for specifying one over the other?”…More

Sweeping Plaza Deck Expansion Joints Under the Rug–The hidden pitfalls of “buried band-aid” joint sealing solutions. Plaza deck, or waterproofed split-slab, expansion joint sealing is serious business. Usually over occupied space, plaza decks are actually heavy duty roofs. Until the emergence of…More

Update: Since securing the following equivalency certification, EMSEAL has secured two CE-marked and fully tested expansion joint systems tested according to EN 1366-4. They include: Emshield DFR/WFR CE with up to 4 hours of fire resistance and Colourseal VHE CE with 90-min…More

Aggregate Loading in Nosing Materials of Parking Deck Expansion Joint Systems So you’ve endured the usual parade of expansion joint manufacturers and their reps through your office. The purpose of these visits is, of course, to get you to specify or buy…More

Abstract The two standards are examined to assess how products evaluated to the UL2079 (North American) standard would be expected to perform when evaluated using the AS1530.4 (Australian/NZ) standard. It was discovered that the AS1530.4 standard does not specifically address building expansion…More

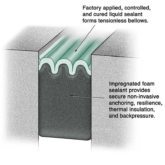

Coated Closed-Cell Foam Sealants–Not Equal to Precompressed, Impregnated Hybrid Sealants. Compression-set limits performance. Why Use Impregnated Open-Cell Foam Instead of Just Closed-Cell EVA Foam? Impregnated open-cell foam is used as the backing for precompressed hybrid sealants because it features very low compression…More

Curved expansion joints follow the curve in the departures roadway at the Jet Blue terminal at New York’s JFK International Airport. The curve is both elegant, functional and ergonomically steers traffic to optimize flow. The roadway is structurally separated from the terminal…More

Article Update January 28, 2020: In addition to the products covered by the technical assessment referenced in this article, Emseal introduces CE-marked, EN-1366-4 certified, Emshield DFR/WFR CE with up to 4 hours of fire resistance and Colourseal VHE CE with 90-min and…More

1. Compression Seal Description: Multi-cell Neoprene extrusion installed into epoxy “lubricating adhesive” applied to joint face. Advantages: Best technology available at its introduction shortly after World War II Predecessor of all modern extruded expansion joint seals Limitations: Anchoring system reliant on adhesive…More

Expansion Joints, ADA, and Spiked Heels — Where do you stand? We are often asked to comment on the suitability of our materials as they relate to Americans with Disabilities Act (ADA) Standards For Accessible Design. Sometimes we are asked to comment…More

More than Just Bridging the Gap: Selecting Floor Expansion Joints for Hospital and Healthcare and Medical Facility Traffic Conditions Floor expansion joints must be engineered to withstand the specific movements and stresses they will encounter. In healthcare floors, any failure can be…More

Hurricane-Fire-Water–Independent Tests Prove EMSHIELD WFR2 Expansion Joint Can Handle it All Testing EMSEAL’s WFR2 to ASTM E-283, E-330, and E-331 EMSEAL’s Emshield WFR2 and SecuritySeal SSW2 are single-install expansion joints with unequaled performance. They are first of their kind wall expansion joints…More

Expansion Joint Resists Hurricane-Force Winds & Water–and Has Air Permeability 2 1/2-Times Lower Than ABAA Requirements Testing SEISMIC COLORSEAL to ASTM E-283, E-330, and E-331 EMSEAL’s Seismic Colorseal has proved itself a workhorse in the sealing of building expansion joints in virtually any…More

Patent Pending Colorseal-on-a-Reel (COR) provides a unique, durable alternative to sealing and insulating window perimeters. In contrast to traditional wet sealing (caulk and backer rod) approaches, COR is tensionless. This means that tensile stresses that cause liquid sealants to fail are eliminated. This…More

Report on adhesion tests between Sika Emseal epoxy and silicones used as “injected sealant bands” and corner beads BACKGROUND: The installation of various of Sika Emseal’s impregnated, precompressed foam sealant systems (DSM, SJS, Emshield, Horizontal Colorseal, DSM-FP, SJS-FP, SJS-FP-FR, etc.) requires the…More

STADIUMS LEAK–But A New Process Yields Better Results It is an unfortunate truth that most stadiums leak at expansion joints. The responsibility for this dubious track record lies with all parties involved. The rare exceptions–stadiums completed with watertight joints–are characterized by a…More

For decades we have known that EMSEAL precompressed foam sealants are good at blocking sound. We just didn’t know how good. Our acoustic-specific product, QuietJoint, is now being widely used to block sound at partition-to-perimeter wall joints and other flanking paths while…More

Video: UL 2079 Testing of Emshield WFR2, Fire-Rated, Wall Expansion Joint System (Powered by YouTube. If your browser has trouble playing a video, visit EMSEAL at youtube.com and follow the plug-in instructions.) The Emshield family of products from EMSEAL are breakthrough innovations…More