Features Explained

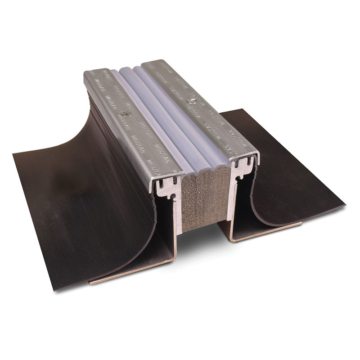

Watertight – Emseal FP (For Plaza) systems are purpose-designed to provide watertight joint sealing and watertight integration with the buried deck waterproofing membrane. The DSM System material is installed between the faces of the FP retainer legs with the silicone bellows facing the weather to ensure watertightness in the joint gap. The tensionless silicone bellows are installed essentially flush to the deck surface just below the stainless steel capping strips thereby ensuring watertightness at the wear-course surface. This eliminates the need for secondary moisture barriers and gutter systems.

Continuity of Seal – All EMSEAL expansion joint systems feature continuity of seal through changes in plane and direction –– an essential performance differentiator. Fabricated transitions from deck to wall, at curbs, sidewalks, parapets, tees, and crosses are available with DSM-FP.

Split-Slab to Solid-Slab Connections

DSM-FP is an effective watertight expansion joint for bridging split-slab and solid-slab construction. The watertight precompressed DSM foam sealant is held securely in place by utilizing the back-pressure of the expanding foam, epoxy adhesive, and a field-injected silicone sealant band at the substrate interface. The connection to solid-slab construction is made directly to the slab substrate. The split-slab connection is made to the DSM-FP mounting leg. The split-slab connection incorporates an integral waterproofing flashing side flashing sheet embedded between layers of the deck waterproofing membrane on the structural slab and beneath the topping slab.

Sizing Criteria

Joint Sizes: Because DSM-FP installs into its own legs, the legs can straddle mean-temperature, structural slab, joint sizes as small as is determined by the designer to meet deck movement criteria.

Joints straddled by the DSM-FP system could be as small as 1/2-inch (12mm) and up to 4-inches (100mm). The minimum gap between the DSM-FP legs is 1-inch (25mm).

(For joints larger than 4″ (100mm) see SJS-FP)

As seen above, the width between the legs of the DSM-FP installed in the topping slab does not need to necessarily be the same as the joint gap in the lower structural slab. The lower gap should be no wider than the width of the DSM-FP foam above it, although cantilevered leg options can be configured to suit special conditions–consult EMSEAL.

Performance and Selection

Movement Capability: 100% (+50% and -50%) of nominal material size.

Leg Heights: 1″ inch (25mm) to 12-inches (300mm)

Note: As joint width increases so does the depth of the DSM precompressed foam–minimum leg heights for wider joints will be determined by the depth of the DSM foam.

Fire Rating

For a similar system with a built-in, up to 2 hour fire rating ask EMSEAL about the Emshield DFR-FP System.

Models:

Model selection is designated by product codes. The code segments relate to the product configuration: For example,

DSMFP-55-400-75 means:

Product

Movement

JointWidth

LegHeight

DSMFP

55

400

75

(55%)

(4″ joint)

(75mm, 3″)

Consult EMSEAL for model number suitable to your specific application.

Installation

- The system consists of two subassemblies: 1) The structural-slab mounted supporting legs with integral waterproofing side sheets; and 2) the joint sealing silicone-faced foam.

- The mounting leg assembly is delivered with opposing legs factory-set to the nominal joint size. It is installed onto a wet-setting bed of epoxy mortar and bolted to the deck.

- The factory-assembled bellows and foam manufactured at applicable widths and depths are shipped from the factory.

- Epoxy gel adhesive is applied to the faces of the previously installed mounting leg assembly.

- The DSM SYSTEM precompressed foam sealant is installed into the joint gap where it self expands into the wet epoxy adhesive.

- Consecutive lengths are joined through the field-application of manufacturer-supplied, low-modulus, high-movement silicone to the intersecting bellows surfaces.

- A field-applied silicone sealant band is injected at the bellows to joint substrate interface to complete the waterproofing.

- With the DSM-FP side flashing sheets pulled out of the way, the deck waterproofing membrane is installed on the deck and broughtover the top of, and up the DSM-FP mounting leg.

- The side flashing sheets are lowered into the liquid membrane (or into the non sag mastic component of a sheet waterproofing system) and sandwiched with another layer of waterproofing. Drainage board and/or protection board are added in accordance with the designer’s preference.

- Concrete, pavers, asphalt, or other topping slab or wearing course material is installed up to the stainless steel retaining caps on the DSM-FP mounting rails with or without a field-applied sealant control joint depending on the wear-course material (consult EMSEAL).

Maintenance

- As with any construction product, the useful life of the material can be maximized with routine inspection and repair if required.

- Clearing of surface debris and inspection will reveal any damage to the product or adjacent substrates that might affect building performance.

- Repair, if necessary of the DSM System foam can be accomplished without removing the FP capping strips. EMSEAL precompressed sealants are easily repaired–requiring only damaged sections to be removed and reinstalled–not the entire length of the joint as is typical of extruded-seal systems.

- For guidance on appropriate snow removal practice click here.

Availability & Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives and/or directly from the manufacturer.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.