Installation

(This is a summary. See Install Data for complete instructions)

Positive-Side Access Installation

Where the construction method is to form free-standing foundation walls leaving access for installation of the waterproofing membrane from the outside of the foundation wall (backfilled wall), the waterproofing membrane is installed up to the joint opening in accordance with the membrane-manufacturer’s instructions.

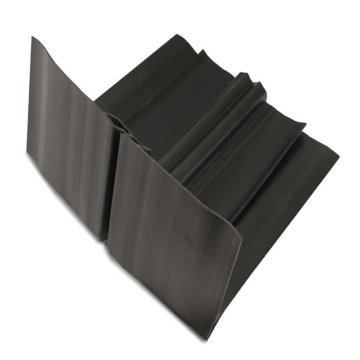

The BG System is installed into the joint. The lower flange is welded or adhered to the outside face of the waterproofing membrane. Termination bars and fasteners are installed over the lower flange of the BG System to anchor the BG extrusion to the wall, and then sealed.

The upper flange of the BG extrusion encapsulates the termination bar, fasteners and lower flanges. Another layer of waterproofing membrane is installed over the upper flanges of the BG System. A protection course and/or drainage board is installed over the entire waterproofing membrane and integrated BG System as prescribed for the application by the waterproofing membrane manufacturer and/or designer. The walls and waterproofing system are then ready for backfill.

Blind Side Installation

Where the structural joint extends through the foundation and base slab, the waterproofing membrane is installed on the ground over the mud-slab, compacted fill or gravel as prescribed by the designer or waterproofing membrane manufacturer, as well as onto the lagged walls in accordance with the waterproofing membrane manufacturer’s instructions.

The BG System sealing gland is integrated into the waterproofing membrane at the center line location of the structural expansion joint opening to be formed and cast later, utilizing accessories and methods recommended by the waterproofing membrane manufacturer.

The BG System termination bar and anchors are installed prior to the concrete being poured, in order to lock the system into the concrete that will be cast over it.

A blockout form is positioned over the belly of the BG System extrusion and the concrete is poured over the waterproofing membrane and BG System sandwich.

The net result is the integration of the below-grade waterproofing membrane and expansion joint system on the positive side (the side that water reaches first) of the wall or floor while ensuring that movement at the joint-gap is properly accommodated.

Note: : Termination bars and anchors may be optional at the discretion of the membrane manufacturer.

Supplied BG System includes necessary termination bar and fasteners when required for installation.

Transitions

The new BG extrusion, featuring dual-level flanges, affords redundancy in anchoring and membrane integration. The BG extrusion is also used in RoofJoint product and the central gland geometry matches that of EMSEAL’s Migutan-FP sealing insert. Consequently it can be welded to RoofJoint across tunnel roofs and under softscaped plazas to ensure continuity of seal.

Similarly, in hard-scaped plaza and split-slab conditions, the new BG System glands can also be welded to the rubber sealing components (central insert and side flashing sheets) of our other FP (For Plaza) systems including MIGUTAN-FP, SJS-FP, DSM-FP, and SJS-FP-FR to ensure continuity of seal.

Transition from below grade walls to above grade walls sealed with Seismic Colorseal is also practically achieved using the appropriate detail for this condition from EMSEAL.

Factory-fabricated transitions–inside 90’s; outside-90’s; tees; crosses; and custom configurations–are available.

Joint Termination at Base of Wall

No Joint in Interior, Bottom Floor

Where the structural joint is designed only in the walls and does not continue through the foundation and floor slab, the BG System is integrated into the waterproofing membrane on the walls and must terminate at the concrete footings at a point designed to be below the elevation of the slab and into a properly designed, active, perimeter drainage system. Details of flashing skirts for footing termination are available from EMSEAL.

Warranty

EMSEAL offers a limited material only warranty for BG System.

The BG System will not perform in conditions that are unsuitable to the requirements for performance of the waterproofing membrane materials into which the BG System is integrated (consult the waterproofing membrane manufacturer).

Consult EMSEAL and refer to warranty conditions, exclusions, and limitations.

Availability & Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives and/or directly from the manufacturer.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.