SafeReseal®

Paintable, precompressed, primary joint sealing system for quick and safe grindless, noiseless, tensionless retrofit installation into EIFS, precast, concrete, and other joint substrates

A joint sealing system for EIFS, precast, concrete, and virtually any substrate, SafeReseal® by Sika Emseal is a safer, grindless, dustless, quiet, primerless, tensionless, paintable, retrofit joint sealant that installs over old sealant residue without the requirement for grinding to completely remove old sealant.

SafeReseal can also be used in new construction as a durable, paintable/coatable alternative to traditional liquid sealant and backer rod.

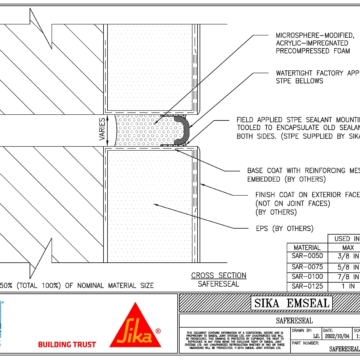

SafeReseal is factory coated with a premium grade, watertight, paintable, hybrid STP sealant and precompressed to less than the nominal material/joint size.

The Sikaflex® sealant has been tested to achieve the requisite adhesion—while under compression from the backpressure of the impregnated foam backing—to the residue of a wide range of commonly supplied joint sealants regardless of age or state (cured, crazed, dried out, reverted, etc.).

Emseal SafeReseal can be installed in a variety of conditions without the need for grinding joint substrates. The elimination of grinding means less noise and less tenant/occupant disruption. The absence of dust means the absence of harmful airborne contaminates like silica and removes the requirement for dust containment, extraction equipment, or specialized respiratory personal protective equipment.

Old joint sealant is removed from the joints using a razor knife. Care is taken to remove as much old sealant as possible without damaging the underlying substrate. After a light solvent wipe, the old sealant is encapsulated with a tooled bead of the supplied STP sealant which acts as the mounting/bonding adhesive for SafeReseal.

The performance properties of SafeReseal are the same as those in Emseal’s technology-defining, Seismic Colorseal precompressed foam technology. The single preformed product outperforms other technologies and provides a durable, watertight seal that creates a thermal block, acts as a sound attenuating barrier, and resists the effects of air pressure differentials, wind-driven rain, and other common forces that cause moisture ingress.