Features Explained

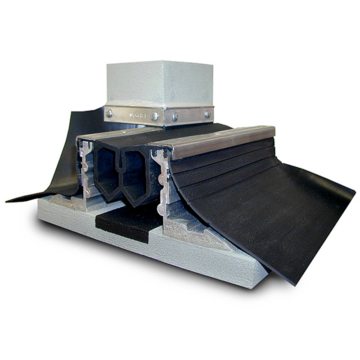

Epoxy levelling — bed ensures that retainer legs are fully supported while acting as a dielectric separator.

Two or three piece interlocked retainer legs are free to slide relative to each other to provide positive interlocking of successive joint lengths. (note: solidleg fp 110/6000s & fp 110/25 interlocked by means of stainless-steel connector pins)

5/16″ x 4″ (8mm x 100mm) epoxy anchors at 12-inch (300mm) centers ensure secure fastening while placing no stress on concrete joint-edge (note: fp 110/25 uses counter-sink-head expansion anchor.)

Level-filled anchor channels protect waterproofing from damage.

Heat-weldable, high-nitrile pvc side flashing sheets are fully embedded in, welded to or adhered to upper surface of primary deck waterproofing.

Overlay and deck membranes encapsulate migutan flashing sheet in watertight sandwich.

Heat-weldable, sealing gland allows for watertight heat-welded transitions in direction and plane.

Stainless-steel retaining caps and machine-screws clamp sealing gland and flashing sheet and are removable for seal maintenance.

Composition

Heavy-duty aluminum, steel, or stainless steel mounting legs are coupled to aluminum top rails. Hard-wearing, stainless steel, gland-retaining capping strips allow long-term maintenance access.

The Migutan sealing insert and side flashing sheets are heat-weldable thermoplastic rubber. This ensures continuity of seal through transitions in plane and direction as well as at terminations.

Positive interlocking metal rails or stainless-steel pins eliminate misalignment between adjoining sections.

Tees, crosses, directional changes, column details, terminations, and changes in plane are available as factory-fabricated assemblies.

Leg heights from 1″ (25mm) to 12″ (300mm) accommodate pavers, asphalt and other toppings.

Exceptional durability under vehicular traffic and extreme weather and temperature conditions.

For watertight transition to below-grade foundation or tunnel walls see BG System.

Unique design incorporates side flashing sheet membranes which embed into and are encapsulated with deck waterproofing membrane to form a continuous, completely watertight system with a static (not in tension) integration to the deck membrane.

Migutan features an unrivalled track record and tens of thousands of feet installed and functioning.

See this article for more on how it works and why to use Migutan instead of a buried type expansion joints.

Design Considerations

The MIGUTAN system is a combination of corrosion-free, aluminum and stainless-steel mounting rail components that are mechanically secured to the structural slab to provide a positive anchoring of the waterproofing components. The metal mounting components ensure that tension, compression, torsional, and other forces that result from joint movement are isolated from the critical connection of the deck waterproofing membrane to the side flashing sheets of the joint system.

The waterproofing components are all state-of-the-art thermo-plastic, rubber materials. These materials can be heat-welded in the factory to produce transitions for addressing changes in plane and direction. In addition these materials can be welded in the field using simple hot-iron tools for attaching transitions to straight runs and to address field conditions as they arise.

Transitions & Terminations

Anybody can make an expansion joint watertight in cross-section. The ability to ensure watertightness through changes in plane, direction and at changes to other expansion joint technologies is a key differentiator for EMSEAL.

It is at these terminations or transitions to other expansion joints in walls or below grade that joint will inevitably leak.

It is critical in ensuring watertightness that these conditions be planned for and addressed wherever possible using factory-fabricated termination and transition assemblies.

EMSEAL has developed a system for the communication of design or field conditions from which factory made transitions and terminations are reliably and routinely produced.

The following are a few examples of the thousands of unique and common conditions for which EMSEAL has manufactured watertight transitions and termination assemblies in the MIGUTAN FP system.

Maintenance

- As with any construction product, the useful life of the material can be maximized with routine inspection and repair if required.

- Clearing of surface debris and inspection will reveal any damage to the product or adjacent substrates that might affect building performance.

- In the event of damage to the sealing gland, the capping strips can be removed and the sealing gland can be replaced or, in many cases, patched by field welding a replacement section into position.

- The durability of expansion joint systems, is significantly affected by maintenance and expansion joint snow removal practices.

Availability & Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives and/or directly from the manufacturer.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.

Testing