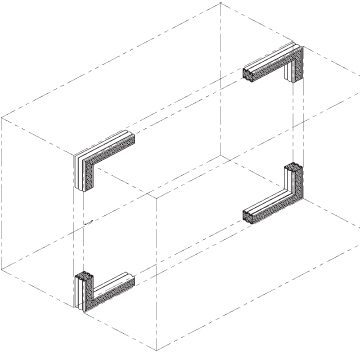

Universal and Custom 90’s

Watertight, Factory Fabricated Upturn/Downturn Transition Pieces For Ensuring Continuity of Seal

Factory-Fabricated Terminations and Transitions — as in all Sika Emseal expansion joint systems, continuity of seal through changes in plane and direction is an essential performance differentiator.

Emseal precompressed, coated, foam sealants are manufactured in straight-run sticks which can be joined in the field to Emseal’s patented and patent-pending “Universal-90” Transitions and Terminations. Universal-90’s are available for all* of Emseal’s coated microsphere-modified-acrylic-impregnated foam sealant products including Seismic Colorseal, Horizontal Colorseal, DSM, Chemseal, DSF, Emshield DFR, Emshield SecuritySeal SSF, Emshield WFR2, Emshield SecuritySeal SSW2, Emshield DFR/WFR CE, Colourseal-VHE, and Submerseal. They have the same performance waterproofing and additional characteristics of the system of which they are manufactured.

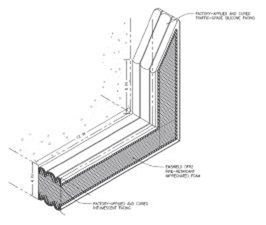

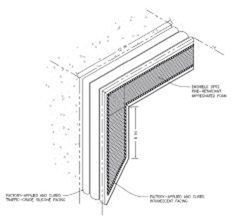

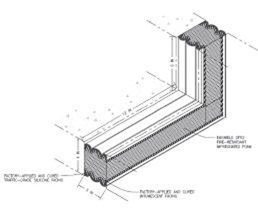

These factory-fabricated single-piece 90-degree units have a 12-inch long leg and a 6-inch vertical piece on each end of the elbow. The Universal-90’s are symmetrically coated on both sides. This allows them to be installed as an upturn or as a downturn.

Universal-90 Transitions are cut at 90-degrees with both ends open for a butt-connection to another stick or another Universal-90. Either leg can be trimmed in the field to connect to straight run material or to another Universal-90 when going, for example, up and over a curb, into a parapet, or up and down treads and risers.

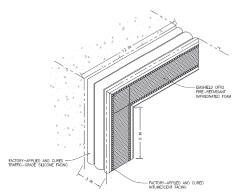

Universal-90 Terminations end, on the 6-inch leg, in a 45° sealed and mitered end. This allows termination as a stand-alone upturn or provides a surface against to which a wall joint system can be married. Flipped over, the Universal-90 termination unit can be alternatively installed as a downturn termination where a joint runs off the deck. In this use, the sealed, mitered end provides a drip edge for drainage of water off the joint.

Custom-90 Transitions and Terminations coated on just the weather-facing faces, are also available when field conditions and measurements are known up front. Consult Emseal. Custom 90’s can be made in all of the products listed above and are the standard way for making transitions in the SJS System, SJS-FR, SJS-FP, and SJS-FP-FR systems.

In addition to guaranteeing a continuous waterproof coating, Emseal’s “Universal-90’s” allow for much faster and secure installation by eliminating field cutting or notching and bending at angles.