SEISMIC COLORSEAL is a watertight, 100% movement, precompressed wall expansion joint. Non-invasivley anchored and tensionless, it is ideally suited to sealing joints in virtually any substrate.

Readily bent, cut, mitered, and joined in the field, Seismic Colorseal makes continuity of seal in similar or dissimilar substrates possible and practical.

Color changes are easily achieved and offer aesthetic versatility not available in other expansion joint options.

Rough CMU block is properly sealed with pliant Seismic Colorseal under the backpressure of the stored strain energy of compression.

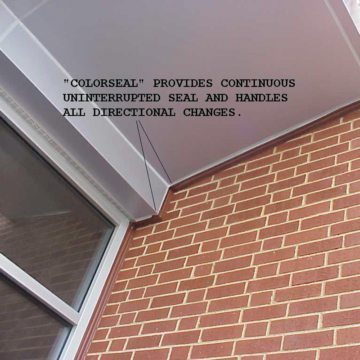

Changes in plane and direction are where expansion joints leak. Seismic Colorseal handles these readily while also providing the option for color switching.

Continuity of seal between different expansion joint technologies is a hallmark of EMSEAL's. Here, Seismic Colorseal transitions to a sloped, sealed, THERMAFLEX upturn termination.

'Black' at an inside corner placement yields a shadow-line effect when viewed from across the street.

A field-applied corner bead of supplied silicone completes the installation and seals substrate irregularities.

Highly versatile and suited to almost any substrate.

Color changes and installation at inside corners are easily achieved.

Seismic Colorseal is a cost-effective, long lasting expansion joint solution in any facade from the fancy to the plain.

Colorseal in precast to window mullion expansion joints installed in 1990 were still functioning as new in 2014.

Resilient, pliant and still pushing back on the substrates 24 years later, Colorseal offers exceptional value to property owners over time.

Skybridges are particularly vulnerable to heat loss as the result of being suspended and require an expansion joint to absorb exaggerated expansion and contraction. Colorseal handles the movement while ensuring R-value is preserved.

Cleverly sited adjacent to a similarly colored downspout, the vertical wall expansion joint sealed with Charcoal Grey Colorseal is hardly discernible to the casual observer.

Shown closeup, Colorseal in the structural wall expansion joint can be seen to be durable and functional even after 13 years of service at the time this photo was taken.

Colorseal in brick expansion joint with matching silicone. The material is pliant and expands into mortar joints to ensure sealing and insulating integrity.

Vertical wall expansion joint inspected 20 years after installation, Colorseal between the Guggenheim Museum administration building and the historic brick facade of its neighbor, is still functioning today.

Precompressed foam joints are ideal for inside corner wall conditions. The backpressure from the foam is what ensures this 9" wide Seismic Colorseal remains in place.

Non-invasive anchoring is crucial for these corner conditions, as it can be almost impossible to maneuver a drill into place to secure a mechanically fastened joint.

Wide seismic expansion joints like this 9" wide Seismic Colorseal are quickly and easily installed into the structural opening. At +/- 50% movement, this product can expand up to 13.5" and compress down to 4.5" wide handling a variety of different movement considerations, such as shear, deflection, wind-sway, seismic, and more.

A near tensionless bond with the adjacent substrates is achieved once the Seismic Colorseal precompressed foam has expanded. A bead of field applied sealant is caulked and tooled to seal off the joint and create a watertight condition.