Hour Glass and Tension in Backer Rod & Caulk

“Hour-Glass” and Tension: Caulk and Backer Rod’s Achilles Heels

Liquid sealants are the most commonly used sealant product for filling smaller joints in building components and control joints. Yet their performance, particularly in moving joints, can suffer from a variety of shortcomings.

These begin with forming the difficult-to-achieve “hour-glass” shape required for their performance. Performance is further exacerbated by other installation factors such as badly prepared substrates and movement during cure.

Finally, tensile stresses at bond lines, as well as within the cured liquid sealant elastomer, often cause premature failure.

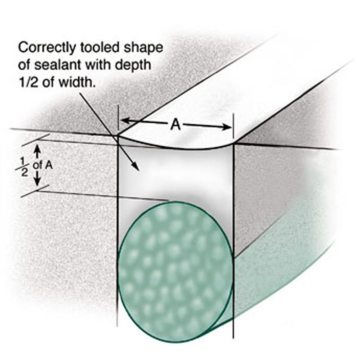

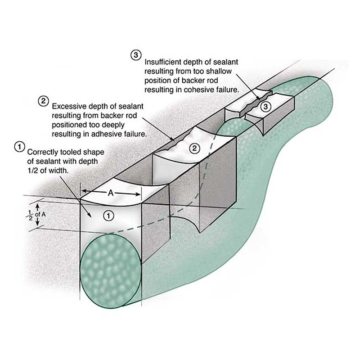

The shape and positioning of liquid sealant foam “backer rod” and proper tooling of liquid sealant is critical to achieving a geometry in the cured elastomer that balances internal cohesive tension with adhesive bond-line tension stresses during joint opening. Achieving this “hour glass” geometry is not easy. Not only must the backer rod be positioned at the right depth, it must be the right size. It is essential to switch backer rod sizes as the joint size changes.

If size switching is not done, the hour-glass shape will never be achieved. Twisting smaller backer rods together to fill larger joints is very common. This practice results in a cross-section geometry nowhere near what is required to give the sealant even a chance to function. The “hour-glass” shape is very commonly not achieved as shown by these examples of liquid sealant removed after failure:

The effects of positioning and sizing of backing material and correct shaping of sealant on system performance during joint opening are illustrated to the left.

But, even if the hour-glass shape is achieved, the “caulk and backer rod” sealant system still relies on adhesion in tension–both at the bond line and within the cured sealant body.

Finding a solution to the shortcomings of field-applied liquid sealants (principally those related to workmanship and dependence for performance on resistance to tensile stresses) was the cornerstone of hybrid sealant research that EMSEAL began in the early 1980’s.

The products Seismic Colorseal, DSM System and numerous others that resulted from this research combine ultra-low-modulus silicone and impregnated open-cell foam. These tensionless, non-invasively anchored products have become industry standards for structural joint sealing.

The technology has been widely accepted as practical for use in these larger, 1 1/2″ and up, joints, but because of cost they have not been considered practical for smaller control joints and building component connections–until recently.

A patent-pending breakthrough in coating and packaging has recently made available a cost-effective, tensionless sealant for small joint sealing in EMSEAL’s Colorseal-on-a-Reel product.

Like its bigger brothers, Colorseal-on-a-Reel provides a lasting alternative to “caulk-and-backer rod” without reliance on a difficult to achieve hour-glass geometry.