Composition

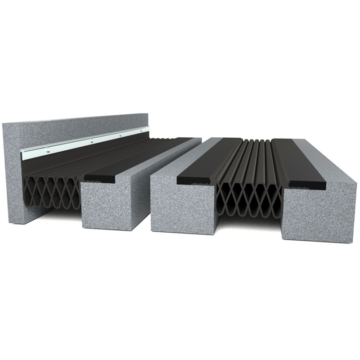

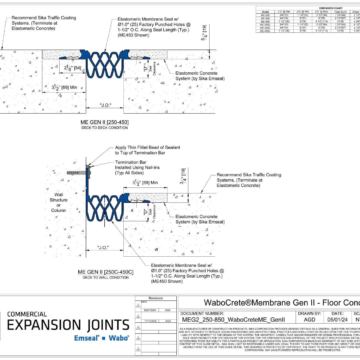

Evolved from the largely obsolete “compression seal“, WaboCrete®Membrane GenII belongs to a product type sometimes referred to as a “winged compression seal.” Innovation to improve movement capability while overcoming compression set and adhesion in tension in extruded seals, led eventually to Emseal’s high-movement, low-strain Gen II series for joints up to 6-inches (150mm).

Built in nosing stop that facilitates efficient installation of the nosing material at a height above the main seal that provides resistance to damage during snow plowing.

Design Considerations

- System will not perform where there is unsound substrate or improper blockout preparation. The joint-gap and the blockout area must be perfectly clean and dry.

- Minimum substrate temperature at time of installation and for 4-hours following installation is 45°F (7°C).

Transitions & Terminations

Anyone can make an expansion joint watertight in cross-section. It is at changes in direction and plane, and between different technologies that joints leaks. Sika Emseal has addressed this problem with custom-quick, factory-made transitions and terminations to fit field measurements. Factory-fabricated assemblies reduce in-field labor time and ensure that continuity of seal is preserved. And, each weld is strengthened with a reinforcing band of welded thermoplastic-rubber sheet and water-tested before it leaves the plant.

Where joint movement is perpindicular to the run of the joint, this will induce shear movement in the seal. Most extrusion can handle only minimal amount of ‘racking’ or shear movement. Emseal’s unique shear pocket technology provides a means to handle large shear movement

Maintenance

- As with any construction product, the useful life of the material can be maximized with routine inspection and repair if required.

- Clearing of surface debris and inspection will reveal any damage to the product or adjacent substrates that might affect building performance.

- In the event of damage to the nosing, the damaged section can be removed, the area primed, and replaced with freshly mixed material. Since the product develops good adhesion to itself, the newly applied section becomes an integral part of the nosing section. The contact surface of the cutout must be free of loose debris, dust, dirt, moisture, and other contaminants. Should the sealing gland be damaged replacement sections or patches can, in many cases, be field welded into position.

- The durability of expansion joint systems, is significantly affected by maintenance and snow removal practices. This article provides guidance on appropriate snow removal practice.

Availability and Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives and/or directly from the manufacturer.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.