Expansion Joint Shear Pockets

Shear Pocket Technology Enhances Movement of Deck and Roof Expansion Joints

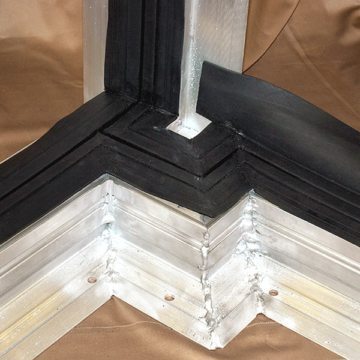

Developed by Sika Emseal over 20 years ago, shear pockets are a loop of Santoprene thermoplastic rubber welded to replace the center member or cells of an expansion joint extrusion.

Shear pockets enhance the ability of transitions in extruded expansion joints to handle extraordinary shear movements where joints change direction and plane.

Shear pockets are an option available from Emseal in the extruded, thermoplastic rubber, Santoprene seals of our Thermaflex TM and TCR, Migutan, and RoofJoint expansion joint systems.

BACKGROUND

Expansion joints are mid-structure separations designed into buildings to absorb movement in building components caused primarily by thermal expansion and contraction. Other structural movements can be induced by wind sway, dynamic and static loading, and seismic events.

Because structural expansion joint openings are a literal gap through the entire structure, they must be bridged and sealed in a manner that restores the functionality of the adjacent building elements. For example, a wall that is designed to keep water out as well as insulate the building and through which a structural expansion joint is placed, needs a wall expansion joint filler that will be watertight, as well as insulate, and possibly be fire-rated, while handling the movements predicted at the joint by the designers.

In a slab, for example in a parking deck, the parking deck expansion joint filler must be watertight, handle vehicle and pedestrian traffic while also handling the expected movements.

Typically, the expansion joint gaps are placed across the structure such that the movements that occur at the opening are perpendicular to the run of the joint.

Similarly, extruded rubber expansion joint fillers suitable to sealing deck joints in the likes of parking and plaza deck structures, are principally capable of handling movements in compression and extension, i.e. perpendicular to their extrusion lengthwise.

SHEAR MOVEMENT

Occasionally, due to design decisions and sometimes design or construction oversights, the run of expansion joints turns or jogs around other building elements. For example, a designer at the owner’s direction or with the intention to economize, might choose to use single-column, slide-bearing design to support two slabs adjacent to a single column rather than using double, split-column design. As a result the structural expansion joint opening between slabs will jog around the column caps on the roof and the column bases on all other levels.

The concrete defining the joint “gap” in the single-column option is free to move if we ignore the need to seal it.

However, when it comes to installing an expansion joint filler, the joint system must now be capable of handling the expected movements in shear at each jog in the run of the joint.

By contrast, while double-column design would cost more, it would provide full support for each adjacent slab while allowing the expansion joint opening between the slabs to run, end-to-end, without changing direction.

Jogs in joint runs can also occur as the result of construction errors or deliberate choices to place other building elements in the path of an expansion joint opening.

Whether by design, error, or oversight, where a joint opening jogs perpendicular to the main run of the joint, shear movements result.

This movement occurs in the opposite direction to the normal folding and unfolding movement capabilities of expansion joint fillers installed to seal and bridge these joints.

Instead, the elasticity of the rubber used in the extrusion, combined with the strength of the joints needed to make the direction changes, must be relied upon to handle the stresses experienced during shear movement.

GLUING vs. WELDING

Before the advent of thermoplastic rubber, extruded rubber expansion joint systems used “thermoset” rubber the most notable brand name being “Neoprene”.

Thermoset expansion systems historically did not do well in handling changes in direction experiencing shear movement. This is because thermoset rubber can only be joined by gluing. The glues that bond well to thermoset rubber tend to be brittle and become more so over time. Under the stress of shear movement these glued connections usually fail.

With the introduction of Santoprene thermoplastic rubber in the 1980’s, the opportunity to weld joins in extrusions was introduced.

Emseal, because it was not vested in Neoprene, was an early adopter of the thermoplastic rubber technology for expansion joint uses. Continuity-of-seal, has always been a defining principle of Emseal’s. Santoprene thermoplastic rubber provided the opportunity to deliver continuity of seal in extruded rubber joint systems.

In general, a weld in Santoprene can be made to achieve in excess of 80% of the strength of the extrusion if properly executed.

When further reinforced with the addition of topically welded reinforcing bands of Santoprene sheet, in excess of 100% of the extrusion strength can be achieved. This process of reinforcing welds is a key differentiator and standard practice of Emseal’s when making factory-fabricated transitions in plane and direction.

As a result, Emseal has proved in thousands of projects comprising more than 1 million feet of extruded rubber product, the ability to handle most shear movements using standard factory-welded transitions and relying on the strength of those welds and the elasticity of the Santoprene thermoplastic rubber to remain watertight.

SHEAR POCKETS

Occasionally, however, a designer presents a condition to Emseal in which they believe that extreme shear movements will occur and/or for which they desire some added assurance. In these conditions, the designer expresses a desire, and is willing to justify the additional expense to the owner, for a system that relies less on the elasticity of the extrusion compound and more on a mechanical means for handling shear movements.

As with all movement calculations and field conditions Emseal relies on the designer and engineer of record, as the parties most familiar with the expected behavior of the structures they are designing, to define the movement expectations and determine the method of sealing.

In these cases the designer may consider to specify a “Shear Pocket”. The shear pocket is a loop of added Santoprene.

As the joint moves in shear, the sides of the Shear Pocket slip relative to each other. While this is occurring, the flexible bottom of the ‘pocket’ twists or distorts relatively free of stress when compared to the elongation of a standard non-shear-pocket weld.

The use of shear pockets is limited to approximately 3% of the Emseal supplied factory welded direction-changes. They are usually specified at the direction of the designer for conditions where clearly defined excessive movements are expected or a concern.

FIELD FABRICATION

It is not practical or feasible to field-fabricate shear-pocket direction changes.

In addition, while Emseal does provide training and on-loan welding equipment for the purpose of field executing butt welds in straight lengths of its extruded rubber seals, Emseal does not endorse field-fabricated direction changes, or field modification of factory-fabricated transitions even without shear pockets. The complexity of cutting clean, straight-and-true mitered angles, welding properly across a seal’s mitered face, smoothing the welding overburden, and field reinforcing mitered welds with Santoprene sheets is compounded by field conditions including among others, space constraints of columns, walls, and other building elements.

SUMMARY

Shear Pockets are a unique method of enhancing shear movement capability in thermoplastic rubber extruded expansion joint components through the addition of a welded loop of flexible sheet material to replace the center joining member or cell(s) of a particular extrusion. As a result the serviceability of extruded seals can be enhanced, beyond the inherent elasticity and geometry of the rubber part itself, for handling extraordinary shear conditions created by design or unintentionally.

The decision to use Shear Pockets is ultimately made by the designer after consideration of field conditions as well as calculations based on their knowledge of the likely behavior of the structure in question. The ability to design and fabricate systems capable of handling these conditions is dependent on the information provided by the designer of record and the installing contractor and the accurate communication of field measurements and conditions to Emseal.

For more on Shear Pockets and their suitability to a specific condition, contact Emseal.

20-year old shear pockets on deck with little or no maintenance. Single-column, slide-bearing design supports decks on either side of a single column resulting in the structural expansion joint jogging around the column cap on the roof level. In the jog, where the joint turns perpendicular to the main run, the joint will ‘rack’ inducing shear movements. In these conditions, as in the example above, shear pockets can be specified, at additional expense, to handle the shear movements mechanically rather than through the elongation properties of the rubber from which the expansion joint seal is extruded.

Typical factory-fabricated transition, without shear pockets, in Migutan FP (for plaza) system with upturn, tee, two horizontal 90-degree turns, and deck-to-wall flange. All direction changes are welded, smoothed and then factory-reinforced. No shear pockets were used on this project which relies instead on the elongation properties of the rubber for integrity.

A Thermaflex TM 2.5 extrusion modified with a shear pocket. The shear pocket is seen extending from below the extruded seal.

Bottom side of Thermaflex TM 2.5 extrusion modified with a shear pocket. Note how the shear pocket is added at the mid-point of the extrusion to replace the center member of the extrusion that divides the outer cells.

Shear pockets can be used to address difficult-to-seal conditions in new and retrofit construction. In this case, two joints intersect in a parking deck at a point just off the corner of a right-angle bend. The result is a “y” intersection that could not be made watertight without the shear pocket technology. A field-made template of the condition allowed EMSEAL to create the drawings from which to factory-fabricate a proper solution using our Thermaflex product.