Features Explained

Watertight — Emshield products are installed with the silicone bellows facing the weather to ensure watertightness. A field-applied sealant band of supplied silicone at the bellows to substrate interface seals substrate irregularities and completes the installation.

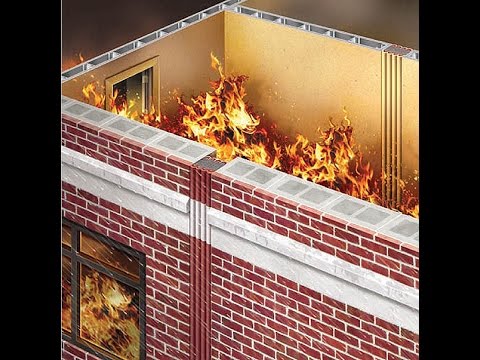

UL/ULC Fire-Rated — Tested in accordance with the cycling and fire endurance requirements of UL-2079, listed by UL, and manufactured under UL’s Follow Up Service ensuring that what is shipped is the same as what was tested.

Non-Invasive Anchoring — There are no hard metal-to-substrate connections with Emshield. This includes embedded pins, anchors, screws, bolts or tracks, trays or rails, flanges or coverplates. The system is locked to the joint faces by means of the 1) backpressure of the foam; 2) the epoxy adhesive, and 3) the injected sealant bands at the joint face.

Joint-Size Variation —through size-switching, material can be supplied to handle variations in joint size.

Sound Attenuation — Joints sealed with EMSEAL impregnated foam sealants offer exceptional acoustic dampening and feature STC/OITC sound transmission coefficients that can meet or exceed that of the assembly into which they are installed.

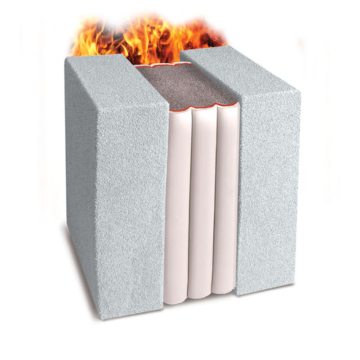

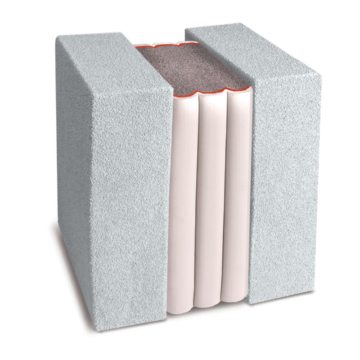

Composition

Emshield fire rated expansion joint sealants features factory-applied, high-grade silicone upper and lower sealing surfaces adhered to a fire-retardant impregnated foam backing. The resulting composite is factory compressed to less than its nominal size for installation into structural or other openings.

The material is installed into epoxy adhesive field-applied to the joint faces. A field-injected silicone sealant band fills substrate voids and seals the bellows to the substrate. Joins between each stick are executed using a field-applied silicone sealant band at the face of the join and an intumescent sealant coating over the remaining foam at the adjoining faces.

Design Considerations

- Capable of +25% and -25% movement for nominal material up to up to 6″ (150mm). For applications in larger joints ask EMSEAL for an engineered judgement.

- Substrates must be clean, parallel, plumb, have sufficient clear depth to receive the material specified, and be capable of resisting 2.5 psi backpressure from the foam.

This material has been tested to UL/ULC 2079 and is manufactured under UL’s Follow-Up Service. The material is being supplied as a fire-rated component of a wall or floor assembly. It has been tested in assemblies depicted in EMSEAL’s various listings in the UL Online Certifications Directory. Use of this material in assembly configurations other than depicted in the named UL listings will not encumber or lower the resistance of the deck or wall assembly but is done so at the designers’ discretion and responsibility for designing substrates as part of a fire rated assembly that meet applicable standards for the project. Similarly, the published information in the UL Listings cannot always address every construction nuance encountered in the field. Authorities Having Jurisdiction should be consulted in all cases as to the particular requirements covering the installation and use of UL Listed or Classified products or materials. Authorities Having Jurisdiction should be consulted before construction to ensure that specific adjacent substrates and assemblies are detailed and constructed to meet local fire-rating requirements.

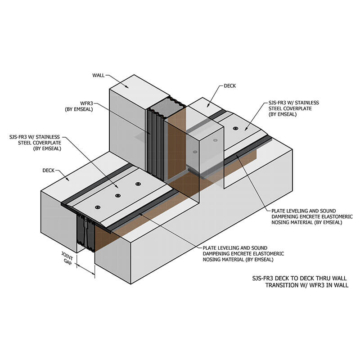

Transitions & Terminations

Universal-90’s & Custom-90’s

(US Patent 9,200,437; 10,066,387; 10,422,127; 10,570,611; 10,794,056)

- Universal-90’s (or U-90’s) are factory-made 90-degree transition pieces that ensure continuity-of-seal and fire protection where expansion joints change plane.

- Use of U-90’s eliminates the field work needed to make plane changes making overall installation fast and efficient.

- Watertightness through the plane change is guaranteed–leaving nothing to chance in field-fabricating inside and outside transitions.

- U-90 transitions are symmetrically coated on both faces allowing them to be installed as an inside corner or as an outside corner.

- Straight-run sticks are joined in the field to the U-90’s.

- U-90’s have a 12-inch (305mm) long leg and a 6-inch (152mm) vertical piece on each side of the elbow.

Custom-90’s

- Custom-90’s are available when field conditions and measurements are known up front.

- Custom-90’s are widely used in stadium tread and riser applications or other applications where numerous inside and outside 90-degree transitions are required. Consult EMSEAL.

Testing

Emshield products have been tested and certified under UL 2079 and meet the requirements of ASTM E1966, ASTM E119 and ASTM E1399. UL 2079, like ASTM E1966, was developed to encompass the fire testing of ASTM E119 and the movement cycling regime of ASTM E1399.

Designers should require UL 2079 testing and Follow-Up Service certification as the basis of specification of any fire barrier system. Only with UL’s Follow-Up Service can the designer be sure that the product being shipped has been independently audited to have been manufactured in the same manner to the material that was tested.

Where UL tested listings do not meet your specific project conditions ask EMSEAL for an engineered judgment. Engineered Judgments are based on our actual UL 2079 test data extrapolated using Finite Element Analysis modeling.

Emshield products have additionally been tested to ASTM-E283, E-330, and E-331 at levels to prove resistance to hurricane-force wind and rain.

Maintenance

- As with any construction product, the useful life of the material can be maximized with routine inspection and repair if required.

- Occasional inspection will reveal any damage to the product or adjacent substrates that might affect building performance.

- EMSEAL precompressed sealants are easily repaired–requiring only damaged sections to be removed and reinstalled–not the entire length of the joint as is typical of extruded-seal systems.

Availability & Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives. For more information, contact EMSEAL.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.