Expansion Joints and Sealants are Critical to Building Enclosure Performance

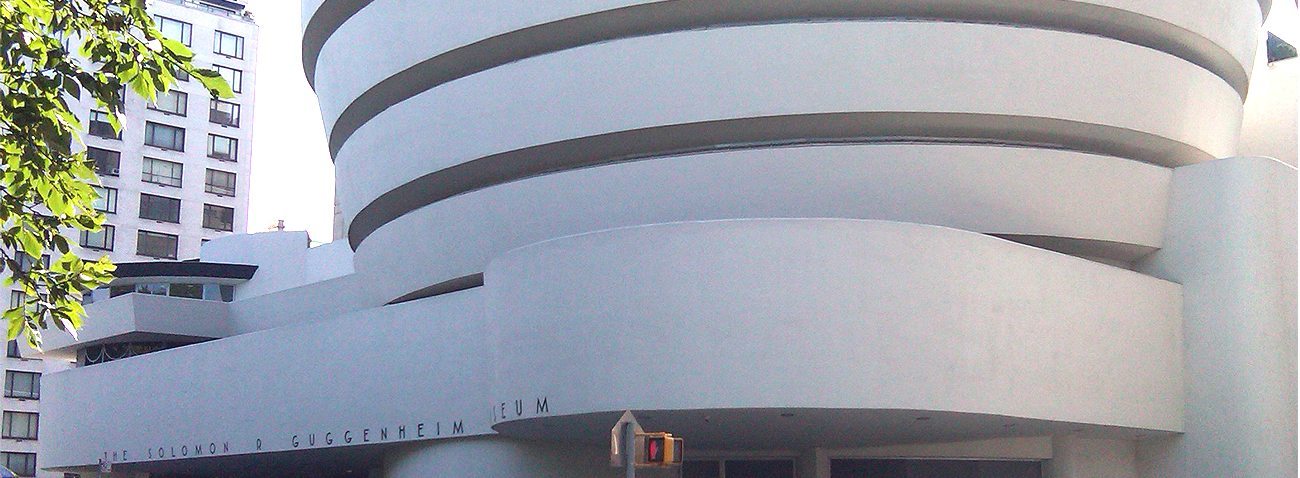

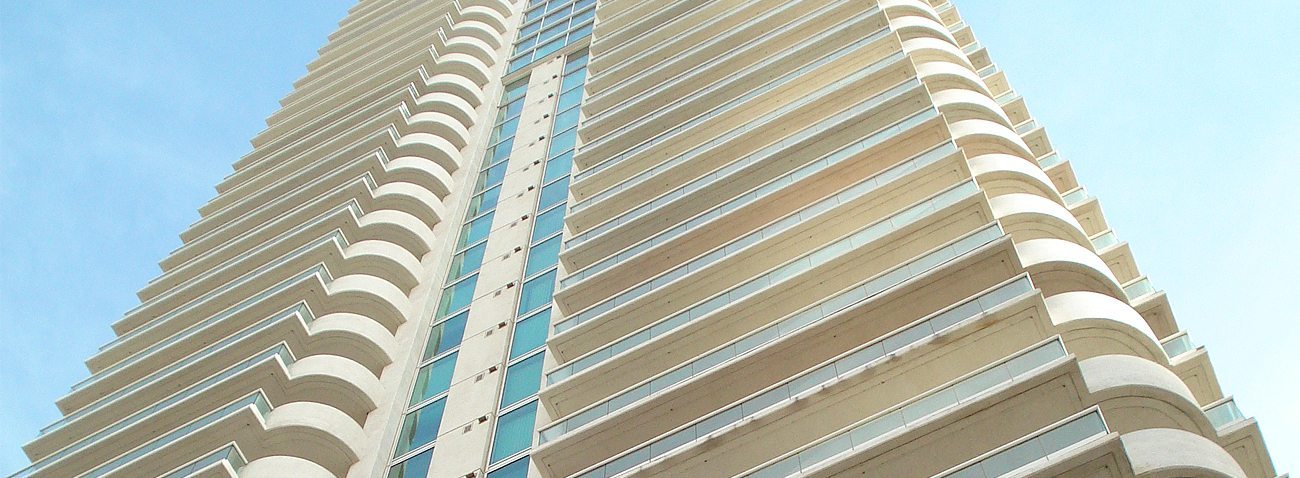

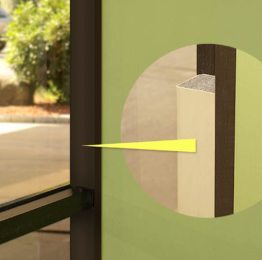

Building expansion joints in concrete, steel, masonry, timber and other structures are a critical element in overall building enclosure performance. Expansion or movement joints bisect the entire structure. This means that structural as well as building enclosure materials specified to waterproof, roof, clad, and cover the structure are divided by the intersecting opening that is the expansion joint. Consequently, in order to ensure build quality, expansion joint openings must be filled, sealed, and/or covered with materials that restore the function of the materials bisected.

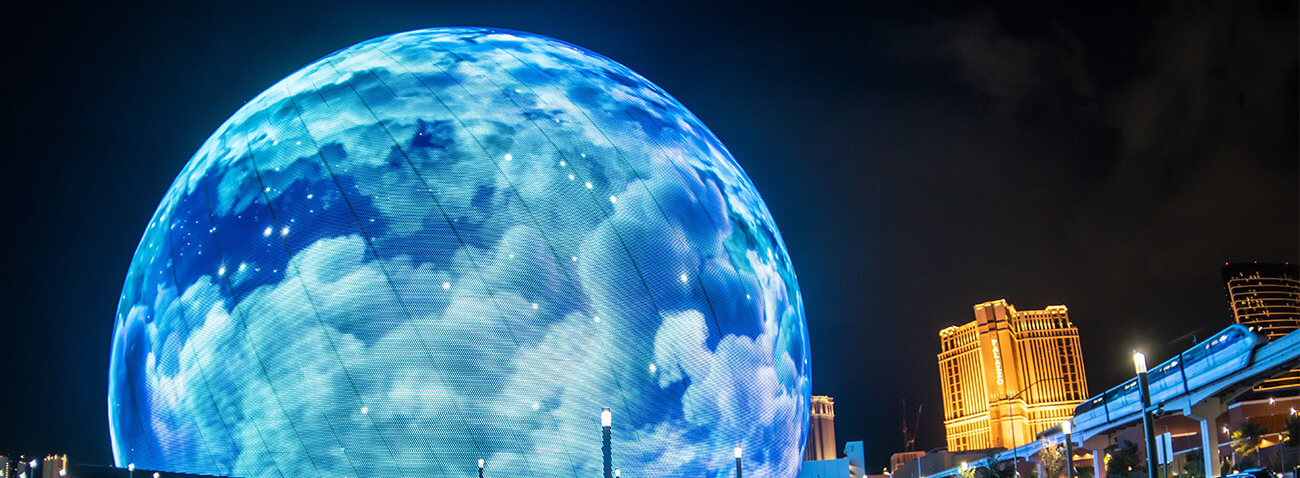

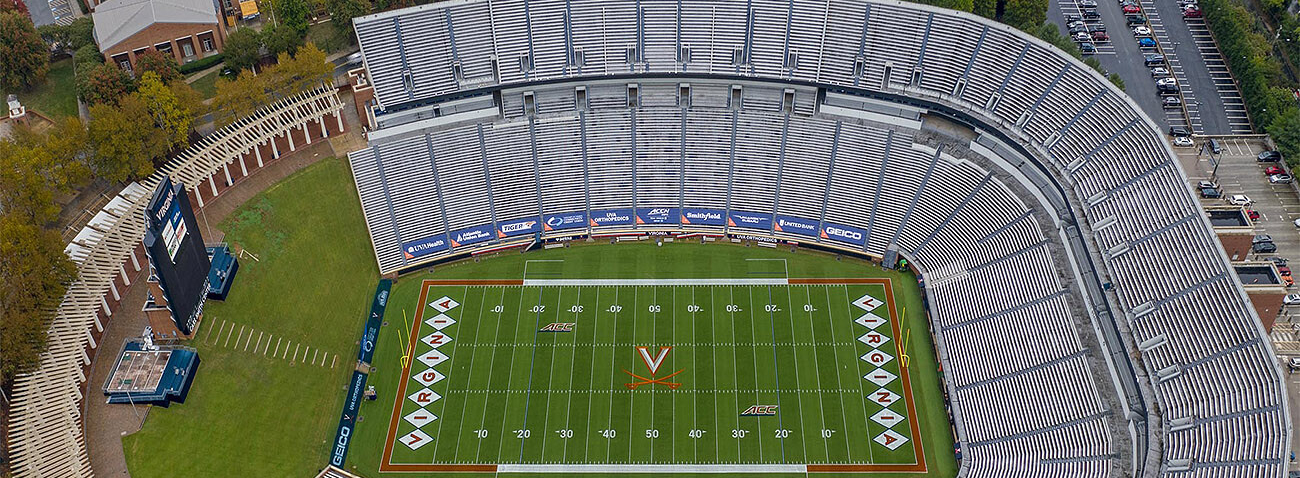

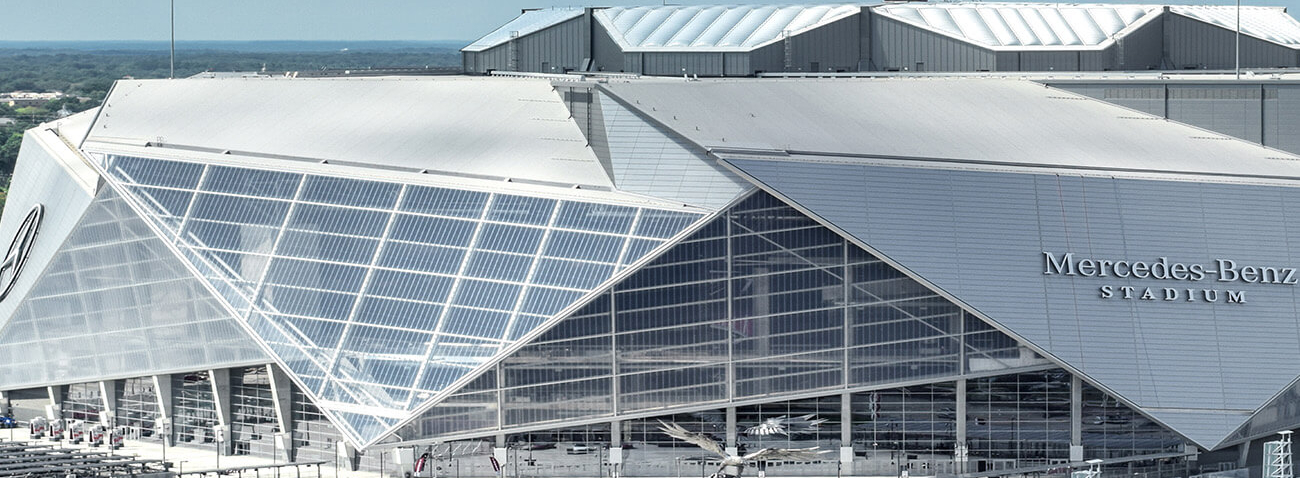

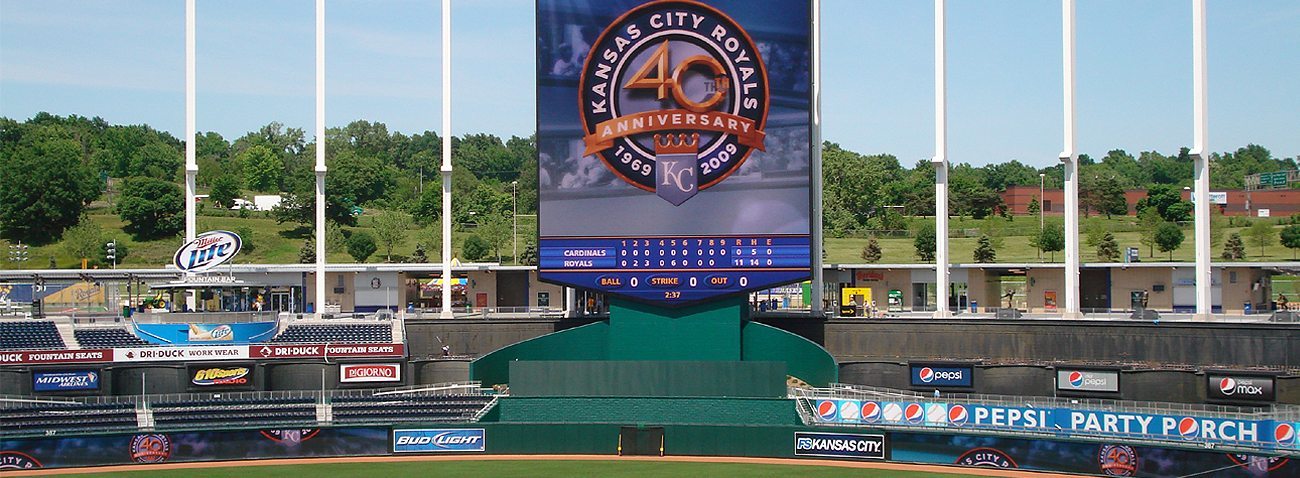

Sika Emseal has used as the inspiration for invention of its building expansion joint product line, the performance requirements of the adjacent building envelope materials. This means that in walls, our precompressed foam sealants were developed to perform to, or exceed, the performance test requirements of curtainwall systems. For roofs, our materials incorporate redundancy across the joint gap, at the roof membrane integration, and even in the anchoring method—by ensuring the roof expansion joint is both welded or adhered and mechanically fastened. For seismic expansion joints, our system innovation was built on principles that ensure watertightness at the deck surface, non-invasive anchoring to the joint substrate, and non-invasive anchoring of the expansion joint covers. In parking garage and stadium expansion joint applications, our systems ensure watertightness throughout curb to sidewalk or tread-and-riser steps as well as in transition to concourses and walls–while ensuring a complete offering to handle a wide variety of traffic (cars, carts, people). When it comes to filling joint openings where acoustic requirements are expected, our solution incorporates mass-loading, absorptive and reflective attributes. And our all-in-one water, acoustic, and fire-rated expansion joints were invented and proved to perform to the strictest fire resistance test methods for fire barriers—UL, ASTM, CE, EN, AS, BS, RWS.

Perhaps most critically, expansion joints will leak if they are not properly transitioned—between similar and dissimilar expansion joint systems at changes in plane and direction—as well as at the tie-ins to waterproofing and roofing membranes and at wall air-barriers and coatings. Sika Emseal ensures expansion joint transitions are properly addressed through collaboration with the design team in ensuring expansion joint layout is communicated in the bid documents, and then through the provision of factory-fabricated expansion joint transitions made to field measurements provided by preferred applicators. As a member of the Sika global family, Sika Emseal is now able to offer complete building enclosure and roof solutions that feature single-source expansion joint warranties between its roof expansion joint (RoofJoint) and best-in-class roof membrane (Sika Sarnafil), monolithic membranes (Hydrotech MM6125), Sika liquid applied membranes (Sika LAM), and Sika traffic coatings.

Purpose-designed products are essential in ensuring build quality and the durable treatment of expansion joints while ensuring continuity of seal between systems and adjacent materials. No less important is the team that delivers this wholistic approach to lasting expansion joint and joint sealing. Our in-field and in-office technical sales team is dedicated to ensuring your project’s success. We use the latest in interactive communication tools and technologies to collaborate with you in selecting products and producing construction documents that help achieve the goal of the delivery of a high-performance building enclosure. These include expansion joint details in BIM, CAD, and Inventor, as well as guide specs, product data sheets, installation data sheets, safety data sheets and so much more available at your fingertips at this website.

We look forward to helping you achieve the lowest-total-cost-of-ownership, trouble-free expansion joints for your project. Contact us today.