Expansion Joint Blog

In its ongoing commitment to quality in manufacturing, distribution, and design, Sika Emseal is proud to announce achievement of ISO certification for 9001:2015 standard for quality management. “ISO certification is external validation of the practices on which we have always run the Emseal plant,” comments Bill Witherspoon, Emseal…

Swimming pools, fountains, water parks and water features pose a real challenge in joint sealing. Durability in chlorinated or salinated water, combined with hydrostatic head pressure make these applications particularly troublesome. Sika Emseal has been simulated continuous head pressure immersion with various pre-compressed sealant configurations and sealant chemistries.…

Sika Expansion Joints companies Emseal Joint Systems, Ltd and Watson Bowman Acme Corp have updated their product portfolio and sales initiatives to focus on specific market sectors. Emseal will continue the sales of Emseal branded Architectural systems, as well as Wabo® branded Commercial, Parking, and Stadium systems. Watson…

Rough expansion joint substrates are actually very common. We were contacted recently about rough limestone and its suitability as a substrate for an expansion joint. It’s a great question because so many of the old technologies — compression seal, strip seal, closed-cell foam — would have left this building…

Sika Emseal’s SWRI-Validated Expansion Joint Training program has been popular among architects, engineers, consultants, contractors, distributors and representatives worldwide. This educational, hands-on installation training program is AIA-registered and offers 8 HSW learning units upon completion. Topics to be covered include: history, design, technology failure analysis, safety, and quality…

Expansion joint products for sealing the building envelope and interior, whether it’s the roof transitioning to walls and decks into below grade as well as structural interior joints, are now available from a single source – Sika Expansion Joints. The expansion joint sealant brands of Sika Emseal and…

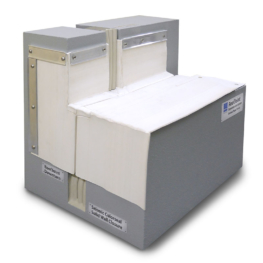

Anyone can make an expansion joint watertight in cross-section. It’s at changes in plane and direction that they’ll leak. That is, unless you order custom, factory-welded, reinforced, leak-tested transitions and terminations from Sika Emseal. This week, like any other, we have a number of jobs on the shop…

We’ve said it before: “Anyone can make an expansion joint watertight in cross-section. It’s at changes in plane and direction that they leak.” Sika Emseal’s process, from design to completion, is built around what we call “Continuity of Seal.” This simple principle ensures that joints don’t leak at…

Our amazing, smiling, weld team continue to crank out parking garage expansion joints customized to follow any changes in plane and direction you throw at them. And, yes, they are smiling! Here they’ve not only taken our Thermaflex winged joint through a complex double/dogleg tee, but they’ve provided…

How often do varying structural expansion joint size problems arise that threaten the success of a project? More often than you’d realize it turns out. Construction would be a whole lot easier if the outcome of all designs was consistent and uniform. But that doesn’t happen in the real…