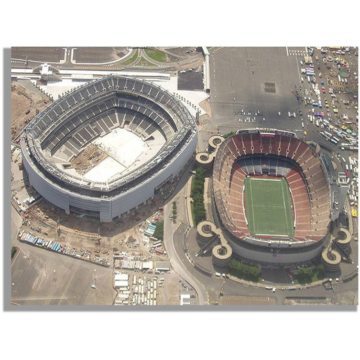

New York Jets/New York Giants, New Meadowlands MetLife Stadium, East Rutherford

New Jersey

Date: 2009, 2018, 2023

EAST RUTHERFORD, NJ–As the Meadowlands prepared itself for its biggest day in football—Superbowl XLVIII—one thing was certain—the stadium expansion joints were ready.

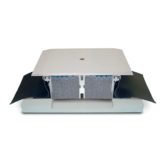

In the same way that the Meadowlands ushered in the era of billion-dollar stadiums, it also marked a watershed in the structural expansion joint industry. With seismic stadium expansion joints 10-inches (250mm) wide, and a design requirement that they be watertight at the deck surface, through all direction and plane changes, between different deck and wall technologies, and capable of handling rolling point loads in concourses and split-slab conditions on the upper decks, the scope of performance expectations was extraordinary.

With design by HOK (360 Architecture), architectural detailing by Ewing Cole, and structural engineering by Thornton Tomasetti, all working under a design-build arrangement with SKANSKA USA, bridging and sealing these large (10-inch nominal) seismic expansion joints fell to Emseal and installer Schnell Contracting Services.

It’s hard to believe that 8+ years have passed since installation began of the 4,200 LF of SJS System and SJS-FP expansion joints in the 83,000 seat, 1.6 billion dollar new Meadowlands Metlife stadium. With stainless-steel coverplates throughout—on the concourses, treads, and even on the risers—the Jets/Giants really did it right.

Even close up, the SJS System is unobtrusive and the long-bevel, flint-blasted coverplates provide an accommodating walking surface.

Here’s how it went down…

…the epoxy-and-sand-coated blockouts were primed using Emprime.

Using a non-sag additive and Emcrete elastomeric nosing material, the blockouts were trowell-filled in the risers, and…

For the mockup, as for the entire project, each tread and riser section of SJS System was custom-fabricated to field measurements made by the contractor. Each piece was labeled and staged adjacent to its place in the bowl. Each piece comes precompressed to less than the joint size and with pre-attached hanger bars to aide installation.

The process is repeated to install all the interlocking tread/riser, foam/spline, custom-90 assemblies of the SJS System.

A unique feature of the SJS System is that the coverplates do not anchor to the concrete. They anchor to the central spline which is flanked by the pre-compressed, silicone-coated foam. This ensures that there are no invasive anchors into the concrete that will loosen over time under loading and movement.

Metlife Stadium features coverplates in the risers as well as in the treads. This is an option. While 1/2″ thick stainless steel was used on the treads, 3/8″ stainless steel was used on the risers. As with the tread plates, the riser plates are anchored by self-tapping, heavy stainless-steel screws into the central spline of the SJS System.

The design team wanted a protective rubber transition piece to bridge the tread to riser coverplate joins. Emseal custom-extruded this piece and factory bonded it to each tread plate.

Cover plate screws are inserted, self-tapped into the SJS center spline below and torqued to their final setting as described in the complete installation instructions.

No detail was spared. At the kick-wall at the bottom of each bowl level, the expansion joint needed to be terminated to prevent water draining down onto the fans below. Custom, continuously-coated closure pieces in the SJS System were made for each condition. Each of these termination pieces runs up, over…

The concourse expansion joints were also sealed and bridged with the SJS System. A factory-fabricated upturn transitions was provided on the end of each run of joint that meets a wall expansion joint. The top of the SJS upturn is mitered and silicone coated to receive a corresponding miter on the bottom end of the wall strip seals.

The finished installation is aesthetically compatible, continuity of seal through the changes in plane and direction is assured, and the SJS System is watertight while accommodating joint movement free of tensile stresses within the expansion joint sealants and free of any hard, brittle, noisy, metal-to-concrete anchors or connections.

In the stadium concourses, the SJS System handles the high point loads of small-wheeled delivery carts; ice-filled, food and beverage concession wagons fork lifts, utility lifts and of course the millions of footfall fans per game.

On the upper level concourse, which acts as a roof for the levels below, the deck is of split-slab design. To ensure watertight integration with the buried waterproofing membrane, the SJS-FP System was used. Supplied with side-flashing sheets and metal retainer legs to match the height of the topping slab, the SJS-FP ensures continuity of seal between the waterproofing membrane and the expansion joints.

The entire SJS System is non-invasively anchored. Because the cover plates are anchored to the foam-suspended central spline of the SJS System, there are no metal contacts into the adjacent concrete. And, because the cover plates ride on a cushion of Emseal’s tough, resilient, but flexible and sound attenuating polyurethane, Emcrete nosing material, the SJS System is not only watertight but arguably the quietest seismic expansion joint available as well.

Revenue loss in affected concession areas, damage to equipment in storage rooms, disgruntled athletes and suite patrons, and exorbitant repair costs are all consequences of leaks at expansion joints.

Elimination of these problems in new sports, assembly, convention and performing arts venue construction as well as in retrofit of existing structures is a central focus of Emseal’s.

The company’s unique approach to sports facility expansion joint treatment combines innovative materials technologies with a fresh look at the roles of owners, designers, general contractors, manufacturers and subcontractors, in achieving trouble-free expansion joints.

The approach is grounded in an integrated, collaborative process centered on joint treatment that requires all of these parties to think, design, detail, specify, construct, fabricate, and install three-dimensional solutions.

Regardless of what happens on game day, one this is certain. The expansion joints at Metlife Stadium are ready for the big show.