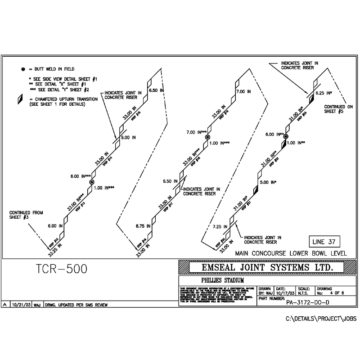

Philadelphia Phillies, Citizens Bank Park, Philadelphia

Pennsylvania

Date: 2003, 2004

Phillies Citizens Bank Park Gets Major-League Stadium Expansion Joint Treatment

Designed with state of the art baseball enjoyment in mind, the 43,500-seat, Citizens Bank Park promises to be the “ultimate baseball and entertainment experience”. The features most obvious to fans will be, according to the Phillies’ website, “natural grass and a dirt playing field … a scenic view of the Philadelphia skyline … an open-air atmosphere and more.”

A feature equally as state of the art as the others but less noticeable to the average fan is the expansion joint treatment. Unlike most new stadiums of the modern era, the owners, and designers of Citizens Bank Park gave expansion joints appropriate consideration–in budget, design, manufacture and installation.

EMSEAL’s approach to stadium joint sealing provides a single source for expansion joints featuring technologies best suited to the many joint applications in a sports facility.

Phillies Ballpark features technologies from a range of options to suit joint conditions while ensuring continuity of seal in changes in plane and direction as well as at transitions between technologies. EMSEAL’s Migutan, Horizontal Colorseal, Seismic Colorseal, and Thermaflex systems were all used, often meeting each other where bowl-to-concourse, concourse-to-wall, bowl-to-knee wall, concourse-to-suite walls, meet. All of these conditions were handled in a manner that ensures continuity of seal within and between each technology.

A closer look at how this was accomplished within the Thermaflex systems used, illustrates how EMSEAL (the manufacturer) and SMS (the expansion joint joint sub contractor) met their obligations under the collaborative approach taken in ensuring watertight stadium expansion joints.

EMSEAL’s Thermaflex technology features heat-weldable thermoplastic rubber from which the tread and riser arrays are produced.

Watertight Expansion Joint Transitions

Each factory-fabricated expansion joint transition weld is reinforced top and bottom and all segments labeled for specific location.

Welded, Reinforced and Water Tested Expansion Joint Transitions

The key to watertightness is continuity of seal–through plane and direction.

Continuity of seal is assured by ensuring that terminations where joints end are made in the vertical plane.

Once installed and locked into the reinforced header material, the treads and riser are watertight.

Blockouts are primed.