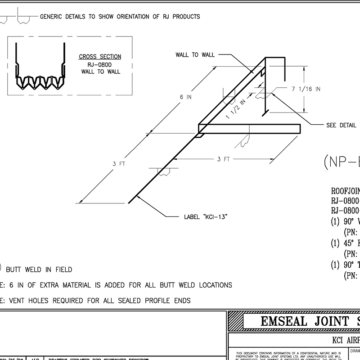

Composition

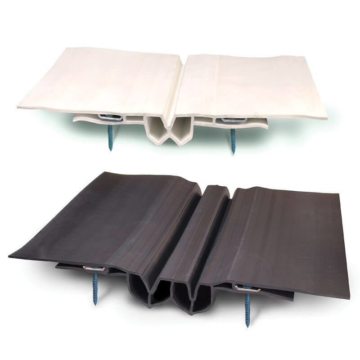

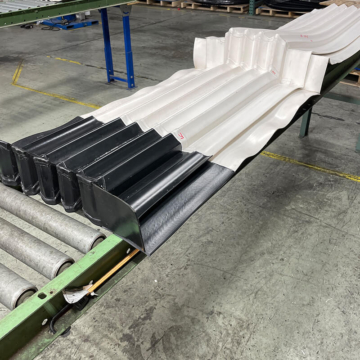

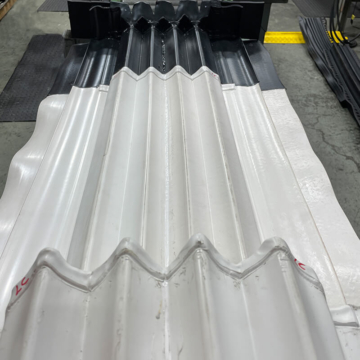

RoofJoint is available in two formulations: Nitrile-Rubber-Plasticized NPVC alloy or TPV (Thermoplastic Vulcanizate).

Nitrile-Rubber-Plasticized NPVC

Used for:

– direct welding to PVC-based roof membranes;

– adhesion into hot or cold-applied rubberized asphalt systems;

– adhesion to SBS membranes

– adhesion into torch-applied mod-bit membranes

The PVC version of RoofJoint is extruded from a Nitrile-Rubber-Plasticized PVC alloy. A Nitrile-Rubber-Plasticized NPVC blend was chosen for this product for its broad compatibility with most roofing systems.

It can be heat-welded to PVC roofs, and subject to the recommended procedures of the particular roofing membrane manufacture in respect to preparation, cleaning, priming, etc., adheres well to the accessories of all adhered (sheet-goods), asphaltic (hot or cold applied), and SBS modified systems.

TPV (Thermoplastic Vulcanizate)

Used for direct integration through welding to TPO (Thermoplastic Olefin) based roof membranes and for integration into EPDM roofing systems.

RoofJoint includes necessary termination bar and fasteners required for installation.

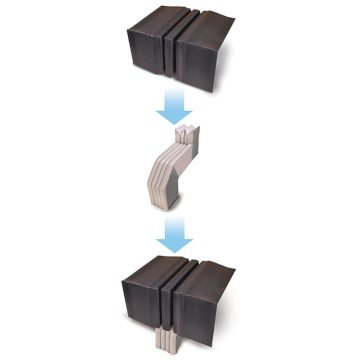

Continuity of Seal

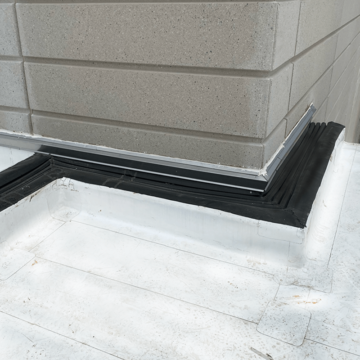

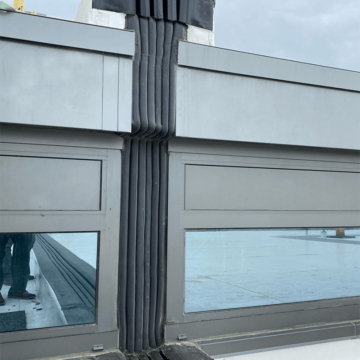

As with all EMSEAL expansion joint systems, continuity of seal is extended to crosses, tees, upturns, downturns, roof-to-wall, and other compound conditions typically found in construction projects.

Factory-fabricated transition pieces can be welded to straight lengths in our plant wherever field measurements are provided and can be butt-welded to straight lengths in the field using simple equipment and training available from EMSEAL. All welds are strengthened with reinforcing strips and leak-checked before shipment.

Closures--Sealing the Wall to Roof Interface

Solid-Wall RoofJoint Closure

Solid-Wall RoofJoint Closure

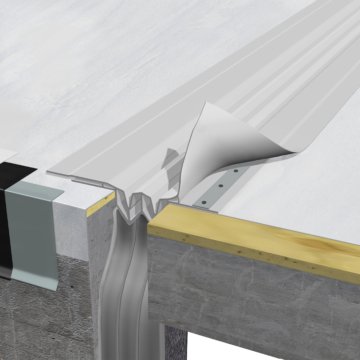

This factory-fabricated transition piece is manufactured from Seismic Colorseal wall-expansion joint material from EMSEAL. This single unit piece has factory-coated silicone bellows on the top and upper-back faces for integration with Seismic Colorseal in the wall and Horizontal Colorseal as a secondary seal and insulator across the roof.

The silicone-coated top side of the closure is shaped to match the underside of the RoofJoint extrusion. The Solid-Wall RoofJoint Closure is installed before installing the RoofJoint. It is installed ¾” down from the roof deck or wood blocking surface. A sealant band of silicone is applied across the upper mating surface of the closure. The RoofJoint is then installed. The underside of the RoofJoint will mate with the top of the already installed closure.

Cavity-Wall RoofJoint Closure

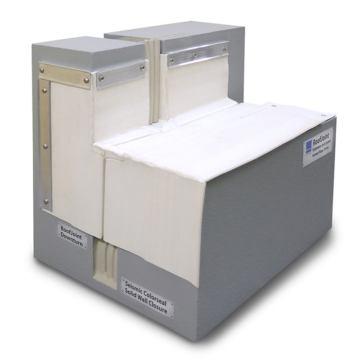

Cavity-Wall RoofJoint Closure

Like the solid-wall closure, the cavity-wall RoofJoint closure, is a factory-fabricated transition piece made from Seismic Colorseal. The difference is an extended, horizontal setback portion of coated foam to bridge the cavity from facade to structural backup wall. The sides of the “bridge” are additionally coated with silicone to seal them against moisture in the cavity and to constrain the lateral expansion of the foam into the cavity.

The underside of the RoofJoint marries to the top of the appropriate RoofJoint Closure. Seismic Colorseal in the wall joint is joined to the RoofJoint Closure. This creates a watertight continuity of seal from the structure’s vertical plane (wall) through the horizontal plane (roof).

Green/Garden/Vegetative Roofs

RoofJoint is ideally suited for use in sealing the structural slabs beneath green, vegetative roof assemblies. Because the growing medium is loose, compressible and granular, movement that occurs at the structural slab can be absorbed without detrimental effect in the green roof overburden. The groove in the extrusion act as a reservoir for excess growing medium moisture while not prohibiting drainage across the joint when needed.

Design Considerations

RoofJoint is ideal for roof, soft-scape plazas, vegetative roof and green roof expansion joint applications.

RoofJoint is also an excellent option for split-slab and hardscaped decks when drainage or other construction may be impeded by the expansion joint protruding above the structural deck elevation. In these cases, an additional expansion joint seal would be needed at the wearing course. See SJS, DSM and DSM-DS.

When the expansion joint requires a fire rating, DFR can be installed directly below the RoofJoint for a single source solution.

For split-slab, podium and other hardscaped decks without drainage or other imitations, see the FP (For Plaza) series of expansion joints from EMSEAL: Migutan FP Series, DSM-FP Series, SJS-FP series or SJS-FP-FR Fire Rated Series offers both with a single product.

Insulation

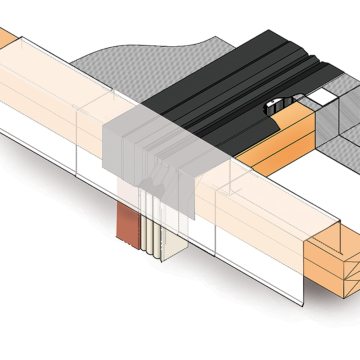

Insulation in the joint opening beneath a roof expansion joint is critical in maintaining energy efficiency in the structure. Insulation under RoofJoint can be achieved in two ways:

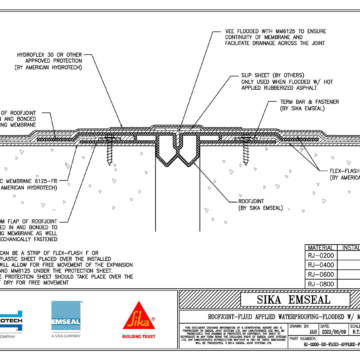

Insulation Method 1: Specify and install Horizontal Colorseal beneath RoofJoint.

The advantage of this solution is that in addition to insulating, the Horizontal Colorseal provides an additional watertight barrier beneath RoofJoint that ties into the RoofJoint Wall Closure transition piece and further ensures continuity of seal and insulation with the wall joint. The R-Value of Horizontal Colorseal is 2.15 per inch of depth. Therefore in a 4-inch joint, Horizontal Colorseal has a depth of 4.5 inches and an R-Value of 9.675. To increase the R-Value of any size of Horizontal Colorseal, specify an increased custom depth.

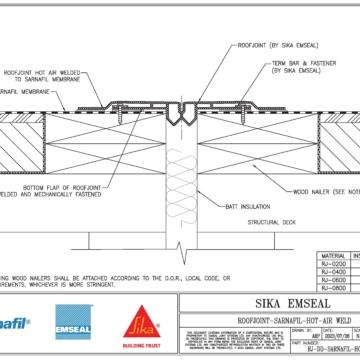

Insulation Method 2: Batt Insulation and Looped Membrane (by Others)

By installing a looped membrane of standard roofing material (by others) to support fiberglass or mineral wool insulation batts before installing EMSEAL’s RoofJoint. While commonly done, this solution provides no continuity of R-value with the wall expansion joint and is subject to insulation value loss through moisture retention due to condensation accumulation in the batt insulation as well as through compression during joint cycling.

Availability & Price

- Available for shipment internationally.

- Prices are available from local distributors or representatives and/or directly from the manufacturer.

- The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.

Solid-Wall RoofJoint Closure

Solid-Wall RoofJoint Closure Cavity-Wall RoofJoint Closure

Cavity-Wall RoofJoint Closure