Buffalo Thunder Resort and Casino, Santa Fe, NM

New Mexico

Date: 2012

Buffalo Thunder Resorts to Colorseal to Replace Precured, Colored Joint

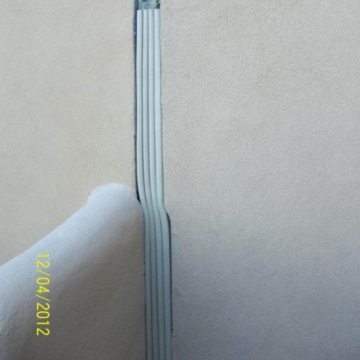

The Problem: The photo on the right is a view looking down an expansion joint from a boom lift. In our opinion, the product, installation instruction and/or installation as performed has led to a failure in the joint at the bond line.

The product is an old concept given a new lease on “life” in recent years under private label.

Whether in its original or rebranded form, “pre-cured caulk and backerblock” systems suffer the same shortcoming — tension. Tension at the bond line and between the liquid sealant and pre-cured sealant down the middle.

Like other systems that exhibit adhesion in tension (the weakest way to use an adhesive), this product and/or its installation may be prone to failure when the joint opens during thermal changes.

The Solution: Colorseal–The genuine and original hybrid, pre-compressed, impregnated foam and silicone, tensionless sealant system from EMSEAL.

Installed by the capable hands of an SWRI-and-EMSEAL-trained contractor, in this case the George D. Alan Company, lasting and trouble free expansion joints are possible.

The first length of Colorseal is installed showing its flexibility and versatility in following contours.

It’s not likely that this intersecting wall was designed to interrupt the vertical run of the structural expansion joint, but it is nice to know there is a product that can handle field-created conditions like this.

The next length of Colorseal is installed and joined to the previously installed length. The join is made with a bead of EMSEAL-supplied, matching silicone applied along the joining faces of the factory-cured, silicone bellows.

Excess silicone that squeezes from the join is tooled away and blended into the factory-formed bellows to ensure freedom of movement.

A close-up of the Colorseal through the jog at the intersecting wall shows the material fully expanded under its own backpressure to completely seal the joint through the contours.

A field-applied sealant band completes the system and is tooled between the outer bellows and the substrates.

The resulting corner bead is never in tension. The cured silicone bellows is never in tension. The system simply folds and unfolds as the joint cycles.

Structural expansion joints are necessary to absorb thermal, wind, seismic and static and dynamic loading movements. But, they are also a gap through the entire building. Colorseal restores the functionality of walls at these gaps by providing waterproofing, insulation, sound attenuation, ABAA air flow resistance, and resistance to hurricane-force wind and water, all while accommodating structural movement in a single non-invasively anchored system.

The bottom line: The bitter taste of poor quality lasts longer than the sweet taste of low price. EMSEAL contributes to the preservation, durability and sustainability of the built environment. We do so by delivering high value, lowest total cost of ownership, structural expansion joints and pre-compressed sealants that work.

Innovation has driven breakthrough new materials that ensure continuity-of-seal against water, fire, heat, cold, air movement, and sound in single product, single installation solutions.

Others are attempting to copy, but specifier and buyer beware…as the Buffalo Thunder Resort learned, it is better to specify and install genuine EMSEAL precompressed sealants.