Expansion Joint Continuity of Seal — Watertight By Design

We’ve said it before: “Anyone can make an expansion joint watertight in cross-section. It’s at changes in plane and direction that they leak.”

Sika Emseal’s process, from design to completion, is built around what we call “Continuity of Seal.” This simple principle ensures that joints don’t leak at transitions within and between joint technologies and that designer, general contractor, manufacturer, and applicator are on the same page when it comes to executing the work.

From 3-D detailing, to specifications, bids, construction of the joint condition, to factory-fabrication of the joint system through complex transitions, this process is geared at delivering property managers and building owners a leak-free, resilient, sustainable, durable building envelope. What are your goals?

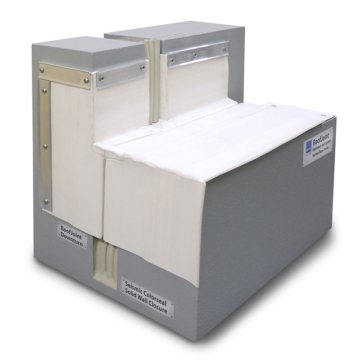

In this mock-up, Seismic Colorseal comes up the wall, is connected to the underside of RoofJoint with a factory-fabricated Seismic Colorseal RoofJoint Closure. The reflective-white RoofJoint features a factory-welded, reinforced, leak-tested outside 90 downturn that marries to the RoofJoint Closure. On the roof deck, the RoofJoint features a deck-to-wall flashing sheet on the vertical plane surface that has been welded into a vertical “boot” to receive the intersecting Seismic Colorseal in the adjacent wall.

“When does this really happen?” you might ask. More often than you think. Four minutes invested in watching this video on the roof-to-wall joint transition is well worth your time.

The real question is, “how will you ensure watertightness at every plane and direction change, and between different technologies?” We think we have the answer.