2-HR Rated Wall Joints in Gypsum WW-D-1081

UL/ULC Listing EMSHIELD WFR2 in Gypsum Wall Assemblies:

System No. WW-D-1081

XHBN.WW-D-1081

Joint Systems

Design/System/Construction/Assembly Usage Disclaimer

- Authorities Having Jurisdiction should be consulted in all cases as to the particular requirements covering the installation and use of UL Listed or Classified products, equipment, system, devices, and materials.

- Authorities Having Jurisdiction should be consulted before construction.

- Fire resistance assemblies and products are developed by the design submitter and have been investigated by UL for compliance with applicable requirements. The published information cannot always address every construction nuance encountered in the field.

- When field issues arise, it is recommended the first contact for assistance be the technical service staff provided by the product

- manufacturer noted for the design. Users of fire resistance assemblies are advised to consult the general Guide Information for each product category and each group of assemblies. The Guide Information includes specifics concerning alternate materials and alternate methods of construction.

- Only products which bear UL’s Mark are considered as Classified, Listed, or Recognized.

Joint Systems

See General Information for Joint Systems on UL’s Website

System No. WW-D-1081

January 20, 2010

Assembly Rating — 2 Hr

Nominal Joint Width — 2-1/4 to 6 in.

Class II and III Movement Capabilities — 25% Compression or Extension

1. Wall Assembly — The 2 hr fire rated framed gypsum wallboard wall assembly shall be constructed of the materials and in the manner specified in the individual U300 or U400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following construction features:

A. Studs — Steel studs to be min 3-5/8 in. wide and spaced max 24 in. OC. Wood studs to be nom 2 by 4 in. lumber spaced max 16 in. OC.

B. Gypsum Board* — Wallboard sheets to be installed to a min total thickness of 1-1/4 in. on each side of wall and on each stud face within joint opening.

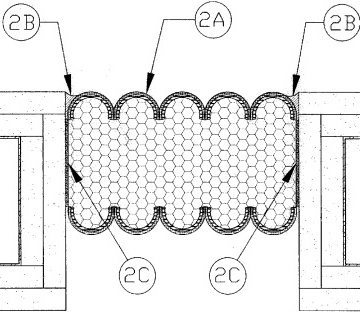

2. Joint System — Nominal width of joint is 2-1/4 to 6 in. (55 to 150 mm). The joint system is designed to accommodate a max 25 percent compression or extension from its installed width. The joint system shall consist of the following:

A. Forming Material* — Compressed, fire-retardant impregnated, 3 ¾ in. deep foam. Topside and underside of foam are coated with intumescent and silicone. Foam is installed in joint opening as a permanent form.EMSEAL L L C — WFR2 Mechanical joint system.

B. Sealant Band — Watertight ¾ in. deep silicone sealant band and corner bead supplied by joint system manufacturer, and installed in accordance with installation instruction.

C. Epoxy adhesive — Consists of two parts; part A (base), and part B (hardener). The epoxy is supplied by joint system manufacturer, and installed in accordance with installation instructions.

*Bearing the UL Classification Mark

Last Updated on 2010-01-20

Questions?

Notice of Disclaimer

Copyright © 2010 Underwriters Laboratories Inc.®

The appearance of a company’s name or product in this database does not in itself assure that products so identified have been manufactured under UL’s Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed and covered under UL’s Follow-Up Service. Always look for the Mark on the product.