(YYC) Calgary Airport Trail Tunnel

Alberta

Date: 2013

Calgary Airport Trail Tunnel Gets RWS-Rated Expansion Joints and Tunnel Roof Lining

Calgary, Alberta, Canada — The $294.8 million Airport Trail Tunnel provides access across the city under the Calgary International Airport.

It does so by running partially under the runways and adjacent taxiways. People, and goods and services providers will use the tunnel. Fuel tankers will use the tunnel. What if one exploded?

The RWS time-temperature curve was developed in The Netherlands to simulate this scenario. It remains the standard against which tunnels today seek structural protection under these extreme conditions.

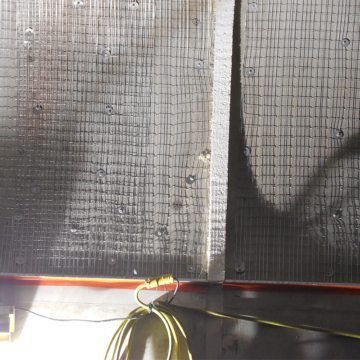

The fireproofing on the the tunnel roof surface is a spray-applied fireproofing material.

Expansion joints through the tunnel roof are a gap in the fireproofing. Restoring the fire-protection across the gaps fell to EMSEAL’s Emshield TFR-RWS rated tunnel joints.

More on the Calgary Trail Tunnel at YouTube

The work of fireproofing the roof and expansion joints fell to Zerodraft Calgary — a full service firestopping and waterproofing contractor.

The Emshield DFR3 was supplied in standard, straight, 2M, lengths as well as in custom curved lengths. The material is pre-compressed to less than the joint size for ease of installation. After removal from the shrink-wrap and hardboard packaging, the material slowly expands into a wet epoxy adhesive to seal the joint opening.

The curved corner pieces were factory-fabricated to match the radii on the inner and outer sides of the tunnel roof to wall transition. Continuity of seal is a hallmark of EMSEAL’s approach to joint sealing and fire protection. Universal and custom transition and termination pieces are available from EMSEAL to address all change in plane and direction conditions.

EMSEAL contributes to the preservation, durability and sustainability of the built environment.

We do so by delivering high value, lowest total cost of ownership, structural expansion joints and pre-compressed sealants that work.

Lasting, expansion joint solutions in airport, mixed-use, retail, office, sports, assembly, convention, casino, resort, healthcare and performing arts venues as well as in retrofit of existing structures is a central focus of EMSEAL’s.

The company’s unique approach to expansion joint treatment combines innovative materials technologies with a fresh look at the roles of owners, designers, general contractors, manufacturers and subcontractors, to achieve trouble-free expansion joints.

The approach is grounded in an integrated, collaborative process centered on joint treatment that requires all of these parties to think, design, detail, specify, construct, fabricate, and install three-dimensional solutions.