Features

Will not dry out and become hard or brittle.

UV-stable and highly resistant to aging and vermin (bugs, rodents, birds, etc.)

Will not extrude from between joints when squeezed, which is a possibility with caulk or butyl-type tapes.

May be used in non-moving gasket-type applications as well as in moving expansion/contraction-type joints.

Sizes

Available compressed thicknesses:

3/32″ (10mm) up to 2″ (50mm)

Equivalent expanded thickness:

3/8″ (10mm) up to 4″ (100mm)

Available widths:

3/8″ (10mm) up to 3″ (75mm)

Download product size chart (pdf)

Movement

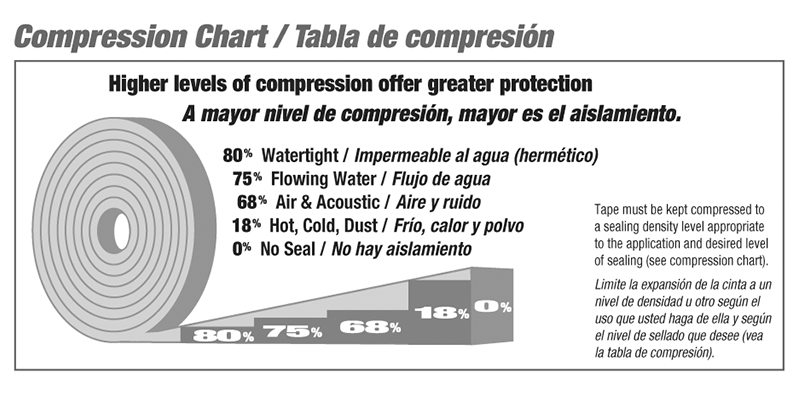

Emseal sealant tapes have different sealing levels at different levels of compression. For applications where movement is expected, and watertightness is required, the sealant tapes can accommodate +25% and -25% (total 50%) movement of the supplied compressed size when installed in gaps equal to the supplied size.

See compression chart below for levels of sealing at respective compression levels.

Color

AST Hi-Acrylic: Black

MST: Grey

Uses

Seal out dust, air, wind-driven snow, and moisture through joint details in metal buildings and similar structures, both pre-manufactured and site-built.

Ideal as joint fillers in expansion/compression seals in joints that are subject to movement from thermal expansion and contraction of a structure, and as gasket-type seals in mechanically fastened, non-moving applications such as lap seams.

Suitable for use against metal, plastic trim, and other materials common in metal building structures.

Use in all applications where the material will be allowed to expand to fill voids.

Provides a durable and versatile solution to these typically difficult-to-seal panel contours at eaves, hips, valleys, peaks, concealed gutters, etc.

Use small-sizes in flat-on-flat “gasket” applications (side laps, end laps, and laps with closures) where the material will be held at a high degree of compression by fasteners such as clips, screws, etc.

In gasketing applications Emseal metal roof and building sealants are hard-working, long-lasting, high-performance alternatives to butyl-tapes which generally squeeze out; or to closed-cell materials which suffer compression set and additionally tend to dry out and crumble.