Where to Buy

Amazon:

All-Purpose/Multi-Use Foam Sealant Tape | Buy Online |

Fastenal:

“Black Sealant Tape” (asphaltic) | Buy Online |

Home Depot:

Universal Seal-Metal Roof and Building Sealant Tape | Buy Online |

Expandable Self Stick Weatherseal | Buy Online |

Home Hardware:

“EMSEAL Self Expanding Foam Weatherstripping Tape, for Metal Roofs” (asphaltic) | Buy Online |

“Self Expanding Multi Foam Weatherstripping Tape” (acrylic) | Buy Online |

McMaster-Carr:

Expanding Foam Tape | Buy Online |

Menards:

Emseal AST Hi-Acrylic 12′ Sealant Tape (asphaltic) | Buy Online |

For sizes not available from the above, contact EMSEAL.

How it Works – The EMSEAL Advantage

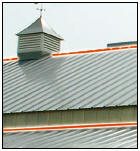

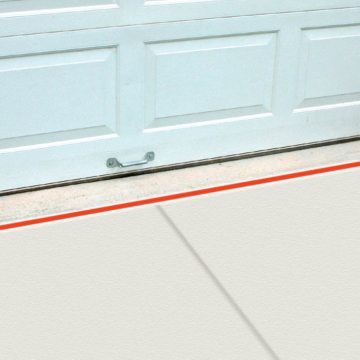

The open-cell foam is impregnated, compressed and shipped in reels. The stored strain-energy of compression in the foam means continuous back-pressure is exerted against surfaces to be sealed. This pressure, combined with the adhesive nature of the impregnation, assures reliable adhesion to both substrates. As the sealed components shrink and expand with seasonal temperature changes, long-term sealing contact with the substrates is maintained.

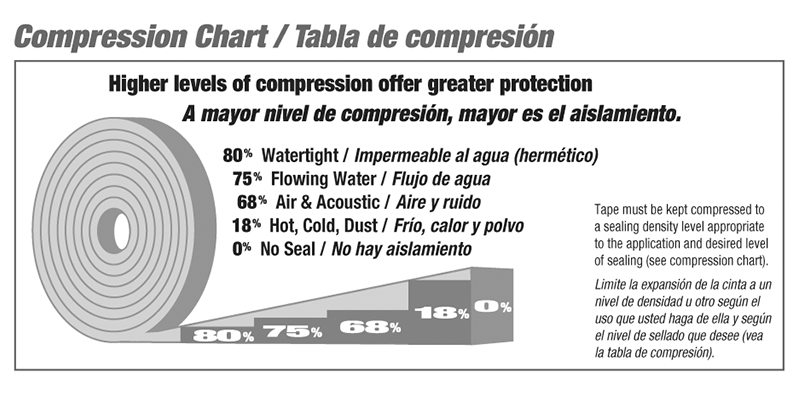

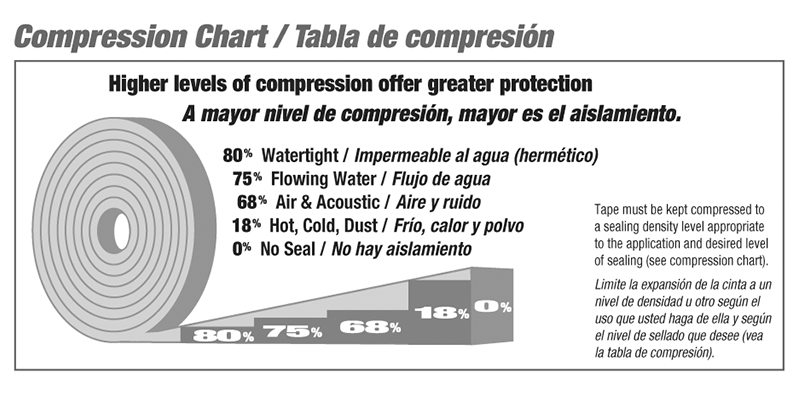

At installation the tape is held to a level of compression suitable to the intended application. Typically, higher compression levels are required for watertightness in water run-off applications; lower compression can be used, for example, for snow seals at roof ridges.

MST is available in a wide variety of configurations. Users determine the size of MST suited to their specific application and performance needs. Typically, higher compression levels are required for watertightness in standing water or water run-off applications; lower compression can be used, for example, for snow seals at roof ridges (see compression chart below).

EMSEAL MST is packaged precompressed in rolls. The material contains a pressure sensitive mounting-adhesive on one face to facilitate installation.

Sealing Levels & Compression

The following indicates levels of sealing at respective installed compression levels:

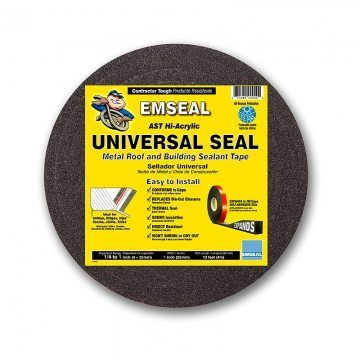

The Choice: Asphaltic vs Acrylic

AST Hi-Acrylic is by volume the most widely used. Black in color as the result of it’s advanced acrylic-modified asphaltic impregnation, AST affords economy without sacrificing performance.

MST features the latest in acrylic chemistry and is grey in color. Choice of MST over AST is really a preference of the user for color and chemistry.

Installation

1. Storage and Surface Preparation

Tape should be stored in a warm dry interior location. Ideal application temperature is approx. 75°F (24°C). Expansion will be faster at higher temperatures and slower at lower temperatures.

Tip: For faster expansion in cold conditions keep the material warm before use and, if desired, apply heat from a hair dryer to installed material to accelerate expansion. Joint faces should be dry and cleaned of dirt, oils, grease, etc. There should exist sufficient depth to receive full width of the sealant.

IMPORTANT: Reels must be stored FLAT and kept compact. Should material expand in package it can still be used. Unroll material, allow it to expand, then recompress it between surfaces to be sealed.

2. Opening Reels

Only open materials that will be immediately used. Remove shrink wrap.

Cut in front of colored marking tape and pull back release liner to expose mounting adhesive.

3. Square Off Ends

Start and finish ends must be cut square. For easier cutting spray knife or scissors with mist of water.

4. Peel Off Liner

Remove release liner to expose adhesive face of tape.

5. Adhere to Surfaces

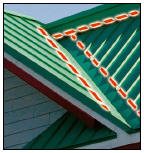

Press adhesive face to one surface. Align other surface with tape. Secure surfaces together. Tip: If needed, cut and fit small filler pieces of tape to fill panel corrugation or voids.

6. Joining Lengths

Overlap one piece of tape with another. Cut through both pieces at a 45-degree angle with a long-bladed knife. Reposition mitered faces over each other and pinch them firmly together to make a join.

Available in many sizes.

If this tape size does not return the results you desire in your specific application, ask your vendor or Emseal for other size options.

Limitations

• Will not adhere to components that are dirty or dust covered or to surfaces coated with oils or other release agents.

• Will expand to follow and fill irregular substrates within reason. Sharp corners and acute angles may need to be filled with additional filler pieces in order to ensure a proper seal.

• Substrate must be capable of resisting, without bending or deflection, approximately 1.5 to 2.5 lb/in2 (10 to 17 kPa) back pressure from the MST.

Availability and Price

Available for shipment internationally.

The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.