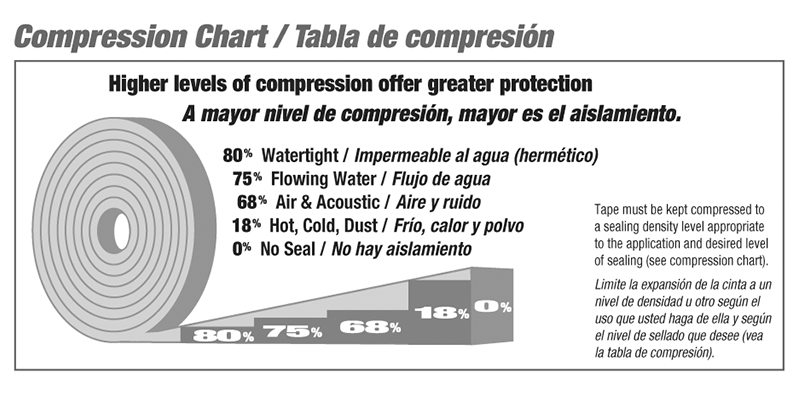

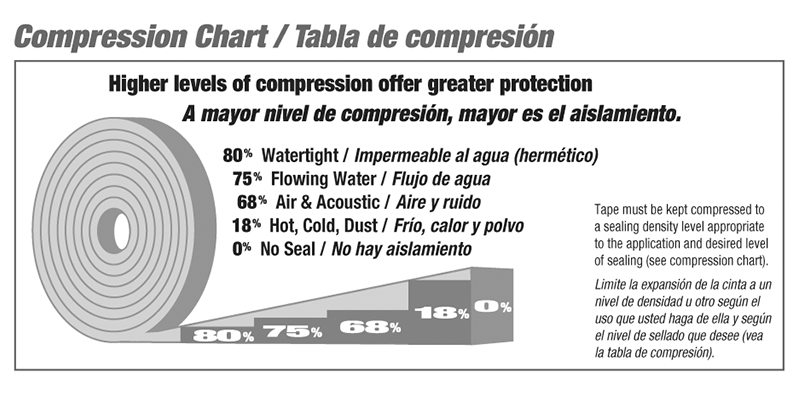

Sealing Levels & Compression

The following indicates levels of sealing at respective installed compression levels:

The Choice: Classic or Acrylic

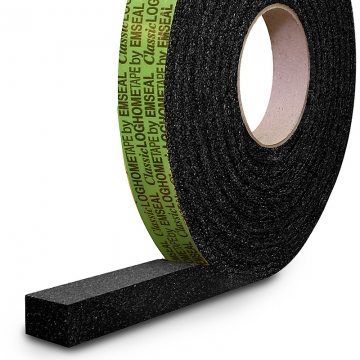

Classic LogHomeTape is by volume the most widely used. Black in color as the result of it’s acrylic-modified asphaltic impregnation, AST affords economy without sacrificing performance and is widely lauded by log home builders for its robustness and durability. Asphalt has been the choice for sealing ships, roofs, foundations, roads and many other structures throughout history. As a result it is not unreasonable to expect that EMSEAL Classic LOGHOME TAPE will last the life of your log home.

Slightly more expensive, Acrylic LogHomeTape features the latest in 100% acrylic chemistry and is grey in color. Choice of Acrylic over Classic is really a preference of the user for color and chemistry.

How to seal your log home

The correct choice of a sealant for the horizontal joints in your log home is as important as your final choice of species of wood. WHY?

• The cost of trying to reseal a log home if the sealant fails, far outweighs initial sealant costs

• The incremental cost of using a high performance sealant during construction may be saved in energy

costs alone in the first few seasons.

• High performance sealants, correctly sized and installed are “lifetime” sealants.

Foam Gasket Choices

Most expanding gaskets are made of either closed-cell or open-cell foams. Exceptions are butyl tape and liquid sealant that relies on adhesion to the log to pull them open.

Closedcell foams are less suitable as seals because their individual cells are essentially gas bubbles which tend to deflate over time. Known as “compression set” this failure to recover typical of closed-cell foams results in the failure of the product to fill and seal changes in gap size caused by movement.

Open-cell foams that have been filled with an impregnating sealant, on the other hand, retain their sealant and recovery properties when compressed to as little as 12% of their original uncompressed dimension.

FACTORS IN COMPARING GASKETING MATERIALS:

• Backpressure – The pressure exerted by the seal against the log surfaces. This must be sufficient to

cause the seal to expand as a gap opens but not so great that it causes “log float”.

• Recovery – This indicates how completely the foam recovers to its original dimension after extended

compression. The higher the recovery percentage, the better the seal.

• Durability – This includes the ability to resist ultra violet light and ozone exposure that can cause brittleness, cracking and ultimately seal failure.

• Wood-Preservative Compatibility – Some foam sealants can be applied to treated wood, others only

to wood that has not been treated. The foam sealant should work with preservatives, whether applied

before or after installation of the seal.

• Ease of Installation – Some foams are self-sticking, with removable release for easy installation.

Avoid Common Mistakes

Sealant sizing: Perhaps one of the most costly mistakes made in log home sealing is to undersize the preformed sealant used between horizontal log courses. The sealant should match the joint-gap size after settlement and shrinkage have been allowed for.

High performance sealant vs. low-cost short-life alternatives:

High performance sealants, properly sized and applied are the better choice. Consider the cost of routing-out and replacing old sealant against the up-front cost of a high

performance sealant.

Check available sealant depth: As the tape width is increased, so does the ultimate margin of safety. However, tape width is also determined by the tongue and groove or other configuration present. Ensure that within these parameters maximum use is made of tape width.

Correct sealant termination: If your log home had no openings (i.e. windows or doors let into the walls), then the correct sealant configuration would be continuous seals running completely around each log course. This means that at each corner the sealant would be lapped to provide suitable horizontal seal integrity. Since openings are present in the structure for doors and windows, seal integrity must be preserved both, horizontally and vertically. Care must be taken to ensure that horizontal and vertical seals terminate into one another.

Double vs. single sealant System: It is generally accepted that the use of a double gasket system is preferable to the use of a single gasket system. A “dead-air” void is created between the two seals which greatly enhances the thermal insulation properties of the log home.

Sealant positioning: Good joint design provides for the seal to be positioned at a high point in the joint detail so that as much as possible, water tends to drain away from the seal

area.

Alaska 5-Star Energy Rating

It had long been considered impossible to achieve Alaska’s highest energy-efficiency rating in a log home. That is until a home was sealed with two strips of EMSEAL LogHomeTape between and at the end-joins of the logs, and with large-size LogHomeTape as compression gaskets in the settling voids above windows and doors.

The result was the first-ever 5-Star, “very efficient” rating for an Alaskan log home.

At settlement joints above windows and doors, LogHomeTape compression gaskets were used to provide excellent insulation and air-infiltration from the outset and are installed in conjunction with a vapor barrier membrane. Over time they’ll compress to a point where long-term watertight sealing is achieved.

The home energy rating is a standard measurement of a home’s energy efficiency. An energy rating allows a home buyer to easily compare the energy costs for homes being considered. The home receives a point score between 1 to 100, depending on its relative efficiency. An estimate of the home’s energy costs is also provided. The home’s energy rating is then equated to a Star rating ranging from a 1 Star for a very inefficient home to a 5 Star for a highly efficient home.

Corner Pads and Saddle-Notch Gaskets

In most applications, LogHomeTape can be laid to follow saddle notches and corner overlaps. In special conditions, Emseal can make corner pads or pre-cut gaskets to seal at corners. Contact us to discuss the unique ways in which sealing these critical areas can be handled using LogHomeTape.

In most applications, LogHomeTape can be laid to follow saddle notches and corner overlaps. In special conditions, Emseal can make corner pads or pre-cut gaskets to seal at corners. Contact us to discuss the unique ways in which sealing these critical areas can be handled using LogHomeTape.

Installation

1. Storage and Surface Preparation

Tape should be stored in a warm dry interior location. Ideal application temperature is approx. 75°F (24°C). Expansion will be faster at higher temperatures and slower at lower temperatures.

Tip: For faster expansion in cold conditions keep the material warm before use and, if desired, apply heat from a hair dryer to installed material to accelerate expansion. Joint faces should be dry and cleaned of dirt, oils, grease, etc. There should exist sufficient depth to receive full width of the sealant.

IMPORTANT: Reels must be stored FLAT and kept compact. Should material expand in package it can still be used. Unroll material, allow it to expand, then recompress it between surfaces to be sealed.

2. Opening Reels

Only open materials that will be immediately used. Remove shrink wrap.

Cut in front of colored marking tape and pull back release liner to expose mounting adhesive.

3. Square Off Ends

Start and finish ends must be cut square. For easier cutting spray knife or scissors with mist of water.

4. Peel Off Liner

Remove release liner to expose adhesive face of tape.

5. Adhere to Surfaces

Press adhesive face to one surface. Align other surface with tape. Secure surfaces together. Tip: If needed, cut and fit small filler pieces of tape to fill panel corrugation or voids.

6. Joining Lengths

Overlap one piece of tape with another. Cut through both pieces at a 45-degree angle with a long-bladed knife. Reposition mitered faces over each other and pinch them firmly together to make a join.

Available in many sizes.

If this tape size does not return the results you desire in your specific application, ask your vendor or Emseal for other size options.

Limitations

• Will not adhere to components that are dirty or dust covered or to surfaces coated with oils or other release agents.

• Will expand to follow and fill irregular substrates within reason. Sharp corners and acute angles may need to be filled with additional filler pieces in order to ensure a proper seal.

• Substrate must be capable of resisting, without bending or deflection, approximately 1.5 to 2.5 lb/in2 (10 to 17 kPa) back pressure from the tape.

Availability & Price

Available for shipment internationally.

Prices are available directly from the manufacturer.

The product range is continually being updated, and accordingly EMSEAL® reserves the right to modify or withdraw any product without prior notice.

In most applications, LogHomeTape can be laid to follow saddle notches and corner overlaps. In special conditions, Emseal can make corner pads or pre-cut gaskets to seal at corners.

In most applications, LogHomeTape can be laid to follow saddle notches and corner overlaps. In special conditions, Emseal can make corner pads or pre-cut gaskets to seal at corners.