Metal Roof & Metal Building Sealant Tapes

Self-expanding, universal closure tapes.

Emseal metal roof and building sealants are self-adhering tape seals made from resilient, open-cell polyurethane foam impregnated with a water-based acrylic-modified asphalt emulsion (AST Hi-Acrylic) or a water-based, acrylic impregnation (MST). They replace and outperform liquid sealants, butyl-tape sealants and closed-cell closures.

Emseal tapes have been the sealants of choice of metal roof and building component manufacturers and discerning erectors worldwide for more than 30 years.

How it Works – The EMSEAL Advantage

The open-cell foam is impregnated, compressed and shipped in reels. The stored strain-energy of compression in the foam means continuous back-pressure is exerted against surfaces to be sealed. This pressure, combined with the adhesive nature of the impregnation, assures reliable adhesion to both substrates. As the sealed components shrink and expand with seasonal temperature changes, long-term sealing contact with the substrates is maintained.

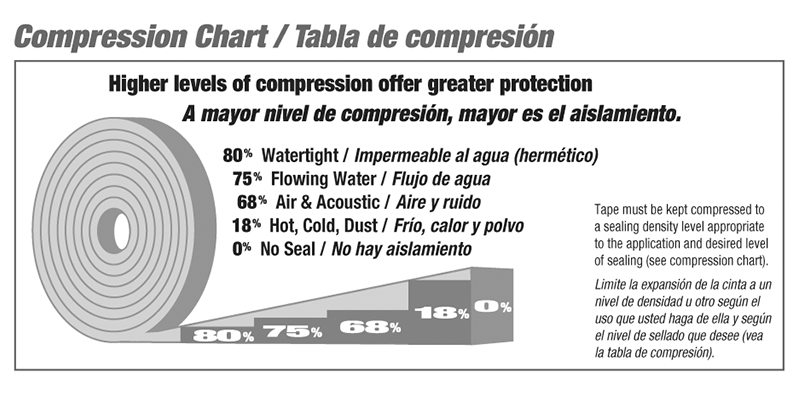

At installation the tape is held to a level of compression suitable to the intended application. Typically, higher compression levels are required for watertightness in water run-off applications; lower compression can be used, for example, for snow seals at roof ridges.