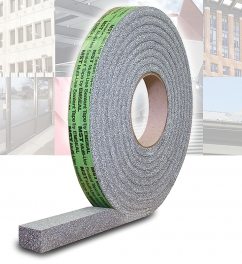

Impregnated precompressed foam sealant tapes. Extraordinary value through durability and performance.

The Difference

Grounded in the latest innovations in impregnated foam sealant technology, EMSEAL sealant tapes are a unique hybrid of the best features of liquid-adhesive sealants infused into a cellular foam matrix that provides resilience, compression recovery and unmatched durability. EMSEAL sealant tapes compress into themselves and do not extrude, or squeeze out like liquid or butyl sealants. This combination of features results in a versatile material suitable to a wide range of uses.

Contact us now to discuss your application and get your FREE SAMPLES for evaluation.

Track Record

For more than 30 years, EMSEAL materials have been used in gasket and OEM sealing applications. EMSEAL’s preformed, precompressed sealant tapes as well as sheets, rolls, pads, and die cuts have be supplied to OEM’s worldwide.

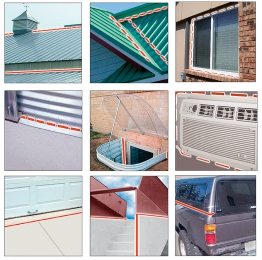

Applications include, automobile, marine, log home, recreational vehicle, awnings, telecommunication shelters, HVAC, building systems, precast concrete building systems, precast walls, precast foundations, windows, metal roof and building systems, retrofit roof drains, and many more.