(OAK) Oakland Airport Seismic Expansion Joints Ready for Flight Traffic

California

Date: 2017

Airport expansion joints should be carefully selected. They need to look good of course. But they need also to be able to handle high-volume foot traffic, rolling wheel traffic, high-point-load maintenance equipment, AND they must be fire rated.

SJS-FR (Seismic Joint System Fire Rated) from Emseal not only does all this, but provides unequal floor-integration design options, features invisible and non-invasive anchoring and is installed entirely from the floor surface. These attributes are significant and only available in a single product with SJS-FR from Sika Emseal.

The result of creative use by AE3 Partners of the customizable SJS-FR coverplates, epitomizes “form follows function.” The construction management of Turner Construction and the workmanship of Mauck Metals, ensured the vision was realized.

Airport Expansion Joint Aesthetics

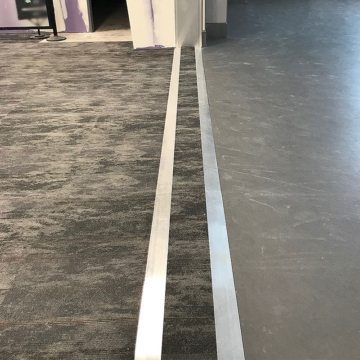

When it’s all said and done, airport expansion joints should look good. A custom inlay-coverplate in the SJS-FR at Oakland provides a recess into which the various flooring types selected are flush mounted. In doing so the desired visual interest and aesthetics can be achieved. In addition, the flooring covers the cover plate screws making them invisible.

The seismic joint systems for OAK were custom configured to suit 5, 7 and 9-inch (125, 175, and 225 mm) wide joint openings and with eight different cover plate configurations to suit field conditions and flooring types.

SJS-FR Installation: Steps and Advantages

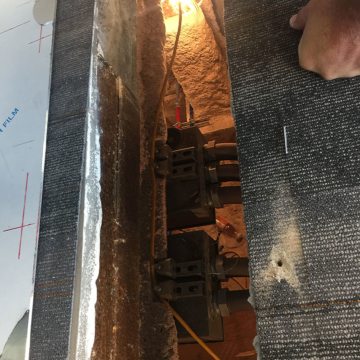

SJS-FR is installed by removing the hardboard and shrink-wrap packaging that holds it in compression to less than the field-measured joint size. The system is lowered into the joint opening where it is held at the proper installation height by factory-installed “hangar bars.” The precompressed foam expands to engage with epoxy adhesive field-applied to the joint faces. The epoxy is supplied by Sika Emseal as part of the system.

Joins between lengths are made by applying an intumescent fire sealant to the foam faces and a bead of silicone to the face of the silicone bellows to be joined. Both sealant accessories are supplied as part of the system as well.

A field-injected sealant band between the silicone bellows and substrate is optional in interior applications but easily achieved, good practice, and further protection against moisture from cleaning operations. Once the system has expanded into place it holds itself in the joint with the backpressure of the expanding foam.

Advantages Over Fire Blanket Fire Barriers

Fire blankets were once the only way to fire proof large expansion joint openings. Installed from below, or looped and protruding below, fire blankets are routinely interrupted by underslab electrical, plumbing and HVAC infrastructure. Interruptions in fire blankets means interruptions in the fire barrier–with serious life-safety implications. Work-arounds are very expensive and often involve rework and work sequence disruption of numerous trades.

With SJS-FR, installation takes place entirely from the deck surface above. Not only does this take underslab infrastructure out of play, but it eliminates the need for staging or utility-lifts, overhead labor, and fall-protection that all add to the installed cost of fire barriers.

Another place SJS-FR and the rest of the EMSHIELD family of all-in-one, fire-rated expansion joints shines over fire blankets is at walls and columns. When a seismic expansion joint run is interrupted by columns or demising walls, it becomes difficult to ensure continuity of the fire blanket between these elements. With SJS-FR the installation of the joint, and the inherent fire protection, is continuous. This is ensures integrity of floor-floor fire compartmentation and provides for a simple integration into the EMSHIELD WFR2, UL-2079 for walls, fire-rated expansion joint system. Not only does the WFR2 ensure fire compartmentation between rooms and the building envelope, but with industry-setting STC and OITC‘s, effectively seals out flanking sound as well.

Non-Invasivley-Anchored Expansion Joint Covers

The hangar bars are removed as the cover plates are laid down. The cover plates are attached to the SJS-FR central aluminum spline. The cover plates are NOT attached to the concrete. This is significant. Cover plates with anchors, embeds, pins and tracks are problematic in concrete floors. They loosen over time resulting in rattling and clattering cover plates.

The inlay recess in the cover plates receives a strip of the adjacent flooring material.