Emcrete II

Lower cost, rapid setting, self-leveling, impact absorbing elastomeric concrete exclusively for bridge and DOT applications.

Impact resistant nosing and patching material for bridges and DOT applications. It stands out as a lower cost solution that meets or exceeds widely accepted criteria of bridge-application nosing materials.

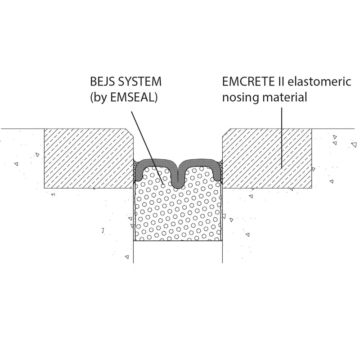

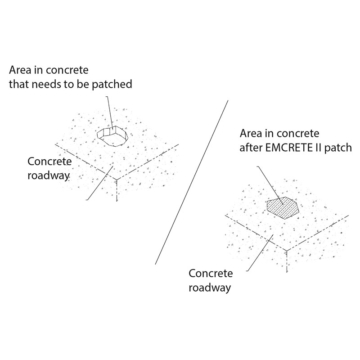

Emcrete II is a flexible, durable, high-impact elastomeric concrete material. It is a non-hazardous, extremely-low VOC product primarily used as a component of an expansion joint assembly either to fill blockouts on each side of a expansion joint gap, to repair a damaged expansion joint gap edges, as an impact-absorbing backfill nosing, or as a fast-curing patching material for potholes, or spalls on concrete roadways and bridges.

Emcrete II is comprised of a two-component polyurethane resin mixed with aggregates. The aggregate imparts compressive strength. The fiber provides cross-linked reinforcement while, in combination with the aggregate, adds body to the polyurethane resin.

EMSEAL’s Emcrete II cures rapidly. This means you can usually install BEJS into an Emcrete II joint header after about 45-minutes. You can turn traffic to Emcrete II used either as patch or as an expansion joint header in 2-3 hours (see “Emcrete FAQ” below).