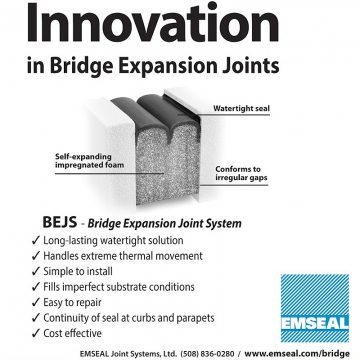

Bridge Expansion Joint System – BEJS Overview

Watertight, traffic durable, new & retrofit bridge expansion joint seal

Bridge Expansion Joint System (BEJS) is a traffic-durable bridge and roadway expansion joint which provides a primary watertight seal. It is designed to handle harsh environmental conditions and features greater movement capability, better low temperature flexibility and higher temperature stability than other technologies. Non-invasive anchoring provides for quick turnaround and repairs. The BEJS System helps prevent and/or decrease maintenance costs to bridge bearing pads and support structures. Primarily designed for D.O.T./Infrastructure markets, it is ideal for new construction and retrofit of old or failed bridge expansion joint systems in: Concrete-to-concrete substrates / Rebuilt joint faces / Where demolition and removal of existing embedded metal angles is not feasible or affordable / As a lasting replacement for all failed liquid-sealant joints in parapets, sidewalks, jersey-barriers, etc.

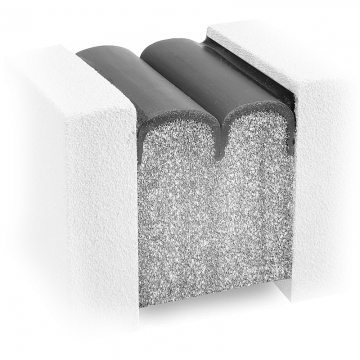

The system is comprised of a precompressed, silicone-and-foam hybrid installed into field-applied epoxy adhesive on the joint faces, with the silicone bellows locked to the joint faces with a silicone sealant band. The BEJS SYSTEM features a hydrophobic acrylic impregnation infused into the cellular foam base material resulting in low-temperature flexibility not available in asphalt, wax, or isobutylene-based products.

Available on reels for smaller gap widths (1/2″ – 1 1/4″ / 12mm – 30mm) or a sticks for larger gap widths (1 1/2″ – 4″ / 35mm – 100mm).