Sizing Bridge Expansion Joints—Joint Movement in Consideration of Lasting Joint Sealing

The lasting sealing of any expansion joint begins with the selection of a sealing material in consideration of the movement at the joint to be sealed AND the movement capability of the product being considered. This is no different in bridges.

No product should be installed if the movement is not known.

No product should be installed based on the product’s published movement capability alone.

Unless the movement at a given bridge expansion joint is calculated, or better still, recorded, there is little chance of a lasting seal.

There are two ways to determine joint movement:

- By actual measurement using an “scratch card” or joint-movement indicator,

- By calculation.

Scratch Card or Joint-Movement Indicator:

A very reliable way to determine joint movement is by attaching a joint movement indicator to the structure.

This simple devise is fixed on one side of the joint and has a pin that scratches a mark on another surface fixed on the opposite side of the joint.

This devise can be field-fabricated (as in the picture on the left) or can be manufactured and adhered to the structure.

This joint movement indicator was installed on a bridge parapet by maintenance engineering crew of MoDOT (the Missouri Department of Transportation). In this case, the screw on the right hand side of the device simply etches the concrete.

The length of the etching is the total movement experienced at the joint over time.

Data on the temperature range experienced over the monitored period is used to calculate the change per degree temperature change.

Theoretical Calculation:

Movement at expansion joints can be calculated using data from the field in cases where the bridge already is built, or from design drawings.

The mathematical formula for calculation of joint movement uses the coefficient of expansion for dense concrete (or other more prevalent structural material) and other factors such as length of span on each side of the joint, temperature range, solar gain, and span constraint.

In order to calculate theoretical movements, the most critical data is:

- The joint gap width at a given temperature.

- The length of suspended decks (slabs) on each side of the joint.

- Whether or not each deck is free to move (unconstrained) at both ends.

Prior to supplying its BEJS (bridge expansion joint system) material for sealing a joint, EMSEAL provides theoretical calculations for consideration by the customer that is based on information gathered in the field as well as from design drawings of the bridge.

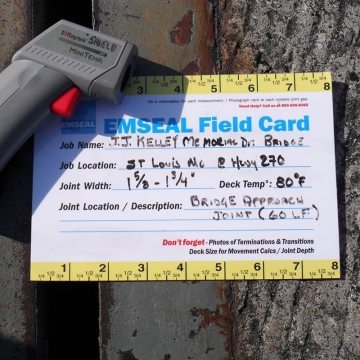

Field information is gathered on a “field card”. Using an infra-red substrate thermometer (left) and measuring wheel, information is communicated to EMSEAL by photograph and email.

Additional information is provided by emailing to EMSEAL a Bridge Expansion Joint Checklist along with copies of the design drawings from the bridge.

From this information, a theoretical movement calculation can be made. EMSEAL uses an expansion joint movement calculation utility we developed for the purpose.

The calculator provides a predicted movement based on the assumptions and data used. This predicted movement is provided to the engineer of record on a project for consideration, and validation, in proceeding with installation of a material to seal the joint.

The calculator also plots the calculated expected movement over a temperature gradient for use in adjusting forms to set or resize the joint opening if the work is performed at a temperature other than mean.

What happens if the data indicates movement in excess of the movement capability of a chosen bridge expansion joint sealant?

If this is the case, then the opportunity must be taken to resize the joint. Resizing the joint involves more or less work depending on whether the structure is new or being retrofitted and whether the joint edges are concrete or armored with embedded steel angles or rails.

New Construction:

In the case of new construction, the movement cannot be measured before the bridge is built. Therefore the sizing of the joint is going to be entirely based on calculation.

Properly made calculations with some safety factor built in, and control of the forming or setting of the joint-gap in relation to temperature, will ensure proper sizing.

Adjusting form widths based on a temperature adjustment table derived by the engineer from the movement calculation data, will ensure that the joint is not made too big or too small for the joint sealing technology selected.

For example, if the calculations determine the joint needs to be 2-inches (50mm) at a mean temperature of 56-deg-F (13-deg-C) and casting of the joint takes place at 95-deg-F (35-deg-C) it will be necessary to use a form smaller than 2-inches to set the joint width. If this is not done, then the joint at mean will be larger than the designed and budgeted width.

Retrofit: Concrete Edged

In the case of retrofits of failed joints with concrete edges, resizing the joint is not a problem as it is usually necessary to remediate the joint edges anyway.

On this project, the spalled edges of the concrete needed to be saw-cut and chipped out and repaired as part of the expansion joint replacement.

With new rebar added to the blockout, the forms are installed and the width checked against the deck temperature immediately before pouring the EMCRETE fast-curing, elastomeric nosing material that will be used to rebuild the joint edges.

The EMCRETE elastomeric nosing material is poured to both repair the joint edge and resize the gap to suit the BEJS system.

Retrofit: Steel Edged

In the case of decks with steel-reinforced joint edges, resizing a joint that has proved too small to accommodate any joint sealant is a slightly more involved process.

This is because it is necessary to remove the metal edge or reinforcing angle–at least on one side.

If the condition of the steel is damaged by snow plows or badly corroded, it is best to replace the steel on both sides of the joint opening.

If the steel is in good shape, then replacement is only necessary on one side.

Resizing would begin with cutting out and removing the steel edge.

The resulting void, or blockout, would then be reinforced with new rebar, a new form of the appropriate width would be set in place, and the blockout filled with a suitable patching material or EMCRETE elastomeric nosing material.

The Bottom Line

Whether by actual measurement using a joint-movement indicator, or by calculation, the only way to ensure the longest life possible of a watertight bridge expansion joint seal is to know the movement that will occur at a given joint.

With this information, and consideration of the movement capability of the product to be used in sealing the joint, a course of action for forming or resizing a joint can be determined.

With a joint properly formed or resized (with adjustments made based on the temperature at the time of work) to suit the the expansion joint material, a lasting watertight joint can be expected.

From a lasting, watertight joint, the big-dollar costs of underside remediation of corroded bearings, beams and piers can be protected and preserved to avoid prematurely needing to redo similar repairs.